With the rapid development of the green energy market, the global demand for wood pellets continues to surge. Many wood pellet manufacturing plants are now facing severe capacity bottlenecks. Wood pellet processing plant construction and expansion have become critical measures for biomass pelletizing factories to enhance capacity and seize market opportunities. However, expansion isn’t just about “building bigger.” It is a systematic project involving capacity planning, capital budgeting, wood pellet plant layout, environmental compliance, and workforce training. This article will explore how to scientifically evaluate the timing of wood pellet plant construction, combined with smart, energy-efficient complete wood pellet production line solutions, to help investors build a more stable and competitive wood pellet plant.

Best Wood Pellet Plant Construction Plan

When Should You Consider Wood Pellet Plant Construction or Expansion?

The global green energy boom has driven rapid growth in the wood pellet market. According to the “China Biomass Energy Industry White Paper 2024,” the compound annual growth rate of the wood pellet market is expected to exceed 12% over the next five years, boosting the entire industry chain. Facing surging orders, investors must scientifically assess whether to invest in wood pellet plant construction to avoid blind investment risks. Here are key dimensions and benchmarks for wood pellet equipment manufacturers reference:

|

Judgmental Dimension |

Core data/Standards |

Judgmental logic (if satisfied, expansion may be considered) |

|---|---|---|

|

Capacity Utilization |

≥85% for at least 3–6 months |

Indicates the current wood pellet production plant has reached its bottleneck |

|

Market Demand |

Confirmed orders/contracts up ≥30–50% |

Stable and long-term growth |

|

Payback Period |

≤24–36 months |

Controllable risk, reasonable financial pressure |

|

Process Maturity |

Forming rate and calorific value difference ≤5% |

Technology supports large-scale production |

|

Raw Material Supply |

Long-term contracts covering ≥70% of capacity |

Avoid raw material shortage risk |

|

Financial Capability |

Sufficient self-owned funds, loans, subsidies |

Ensure project execution |

|

Environmental & Approval |

Reserved space and power, emission standards met |

Ensure legal compliance |

A professional evaluation, combined with your company's strategy, helps create a practical wood pellet plant layout and construction plan. You’re welcome to contact ABC Machinery to get a free customized evaluation and industry-specific solutions.

Step-by-Step Guide to Pellet Mill Construction and New Wood Pellet Production Lines

Want to lower wood pellet making equipment energy consumption, increase output, and meet international standards? Below are ABC Machinery’s core technical solutions and data advantages to help you design a smarter, greener wood pelleting plant.

Select Best Wood Pellet Production Line for Sale

New High-Efficiency Drying Solution Cuts Energy Use by 30%

-

Supports raw material moisture 10%–55%, with smart temperature control at 120–160℃.

-

Dust removal efficiency >99%,emission concentration below 50 mg/m³; noise ≤75 dB.

-

ABC Machinery developed the hot air circulation + waste heat recovery machine, integrated with the wood pellet production line PLC automatic monitoring, wood pellets before leaving the factory, the whole machine dedusting, sound optimization design.

97%–99% Forming Rate and Fast Size Switching

-

Supports 6mm, 8mm, 10mm pellets,wood feed pellet production line mold changeover in 15 minutes.

-

Continuous operation time >3000 hours,wood pellet size tolerance within ±0.2mm.

-

ABC Machinery self-developed hot air circulation + waste heat recovery machine, integrated with PLC automatic monitoring of the wood pellet production line, and optimized design for dust removal and sound insulation of the whole machine before the wood pellet leaves the factory.

Multi-feedstock adaptation and production cycle shortened to 7-14 days

-

Supports raw material moisture 12%–50%,wood feed pellet line consistency improved by 30%.

-

Modular installation in 7–14 days,taff training in 3–5 days.

-

ABC Machinery's customized crushing + screening + humidifying system, with standardized modules pre-installed, helps wood pellet manufacturers to achieve stable batch production quickly.

Precise Quality Control & Export Compliance

-

Detection precision ±0.1mm,wood pellet plant auto-sieving efficiency >99%.

-

Project design cycle: 4–6 weeks,wood feed pellet mill after-sales response ≤24 hours.

-

ABC Machinery Equipped with online weighing and size inspection system, fast delivery team and project manager to ensure on-time delivery,dedicated wood pellet export line meets European CE and environmental standards.

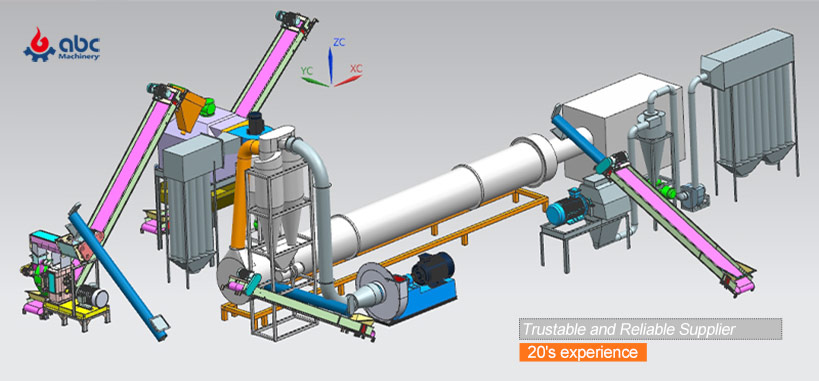

3D Drawing of Wood Pellet Plant Construction for Sale

Why Choose ABC Machinery for Your Wood Pelleting Plant Construction?

Wood pellet mill construction is a major strategic decision. ABC Machinery helps pellet equipment manufacturer control risk and upgrade capacity quickly, offering:

-

20+ years of industry experience & wood pellet market insights.

-

98% on-time delivery rate for wood pellet production projects.

-

Pilot wood feed pellet lines to shorten wood pellet process verification by 30%.

-

wood pellet plant flexible switch time <2 hours to meet market demand.

-

wood pellet manufacturing line ROI prediction accuracy up to 95%.

-

Free feasibility consultation to reduce wood pellet plant blind investment.

-

Financing solutions to boost wood pellet making line flexibility by 40%.

Factory Price Wood Feed Pellets Production Plant

ABC Machinery combines patented wood pellet manufacturing equipment with modular wood pellet production line design and smart process optimization, helping you reduce energy costs and respond quickly to wood pellet market changes. With full export certification and professional technical support, your investment will remain competitive and sustainable.

In today’s fast-changing market, planning your wood pellet plant construction early means lower risk and higher market share. Addressing bottlenecks, process upgrades, and compliance is key to sustainable growth. Contact ABC Machinery now for a free customized expansion evaluation and professional guidance—let us help your biomass pellet plant reach new heights.