Sustainable resources and bio-fuels are the future for many industries. One area of particular interest to companies and investors world wide is the fuel pellet maded from recycling coffee grounds and husks. We make a successful test run of pelletizing coffee wastes for one of our new Indonesian client. We have made the test of extruding of coffee husk pellets for one of our Swiss before, bust this time the test is more comprehensive.

View the photos below to see the compression moulding effect of coffee residue

for your reference.

Our small biomass pellet machines were able to create high-quality coffee ground pellets and coffee husk pellets with a moisture content of 63.3%. Therefore, we are keen to welcome orders from other clients that may be curious about our coffee husk pellet mill.

| MODEL | POWER | CAPACITY (kg/h) | WEIGHT (nw/gw) | PACKING SIZE (mm) |

|---|---|---|---|---|

| ZLSP-D 200B | 7.5 kW | 80-120 | 200/230 | 1050x480x930 |

| ZLSP-R 300B | 22 kW | 250-350 | 540/575 | 1350x750x1400 |

- The pelletizing test of coffee husks is done by R-type 300B Pellet Machine.

- The pelletizing test of coffee grounds is done by our D-type 200B Pellet Machine.

Testing Report of Coffee Husk Pelletizing Process

Coffee husk is the main by-product after de-hulling the coffee cherries during dry processing. Although the husks can be processed directly in pellet machines , but you are suggested to crushing the husks before making pellets, so that to get better result.

Testing Report of Coffee Husk Pelletizing Process

The application of waste coffee grounds for making biomass pellets is getting more and more people's attention. Take this testing report for reference if you are also planning to invest in this field.

The raw moisture content of coffe grounds for the test is as high as 63.3%. Drying is needed before feed them into pellet machine, or the produced pellets will be easy to break and have cracks.

Processing of Mixing Coffee Husk and Grounds

We have done a series of tests with different moisture content and different mixing ratio of the husks and grounds. The conclusion is that mixing is not a good idea. It is suggested to process the coffee hulls and grinding wastes separatly. Some of the coffee residue pellet samples are listed below.

Running Video of Coffee Grounds and Husks Processing in Small Pellet Machine:

How pellets are made from coffee wastes?

Coffee producers end up with large quantities of waste products in the form of coffee husks and coffee grounds. But, there is no reason to discard these by-products entirely when they can be put to better use. Both the coffee husks and grounds have potential when it comes to these alternative fuels. The pelletizing process essentially creates tiny bursts of energy that are perfect for heating systems and boilers — both on a residential and more industrial scale.

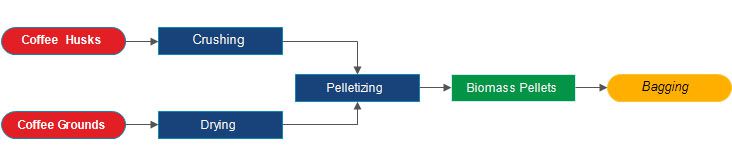

Coffee Wastes Pelletizing Process Flow

Our pellet machine transforms the original by-product via a series of rollers and dies within its chambers. A lot of work goes into this transformation process. The materials must be dried carefully to remove the moisture content. The dry materials are then crushed and reformed into a compact pellet shape. (You may be also interested small biomass pellet production unit >>)

Small-sized Pellet Machines for Sale

Be aware that there may be not be enough calorific content in the raw coffee materials alone. This is when producers add in other materials such as corn cobs and peanut shells. It is all about creating a high value pellet with enough potential as fuel. Once the pellets are cool they are packed up ready for transportation.

Why are these reformed coffee husk and coffee ground pellets so beneficial?

- Low-cost, High-Value

- Higher Potential Value than Agricultural Pellets

With time, the demand for these biofuel pellets processed from coffee ground and husk will grow even further. Coffee husks and grounds will be better appreciated as valuable by-products rather than seen as waste. These processes and advantages prove the worth of the industry. Until then, we encourage you to stay in front of the trend with our coffee husk pellet mill services.