- Capacity: 600~1000kg per hour;

- Pellets Diameter Range: 2~8mm;

- Application: making feed pellets for feeding geese, duck, chicken, rabbit, sheep, cattle, pig, fish and other poultry, livestock and animals.

Small Scale Animal Feed Pellet Machine Set

STLP 300 and STLP400 animal feed pellet machine is a small poultry feed production line (600~1000kg/h), which includes system of grinding, mixing, conveying, pelletizing and cooling. The diameter of final feed pellets can be 2~8mm. It is a multifunction poultry feed pellet making machine which is suitable for processing feed pellets for various kinds of poultry, livestock, and animals. Don't hesitate to inquire for detailed quotaion of this small plant!

Parameters of STLP Series Mini Animal Feed Pellet Line

| Model | Power (Kw) | Capacity (kg/h) | Weight (kg) | Dimension (mm) |

|---|---|---|---|---|

| STLP300 | 45.7 | 600-800 | 2464 | 15000*4000*4500 |

| STLP400 | 61.2 | 800-1000 | 2902 | 15000*4000*4500 |

Highlights of the Mini Feed Pellet Production Line

- Low Investment: Due to compact structure design, this feed pellet machine set is featured of low requirement on space and workshop conditions.

- Low Installing Cost: The installation of this small feed pellet plant is very easy. All the machines can be used directly after simply connection.

- Low Production Cost: Only 1~2 workers are enough for the operation of the complete plant. Less labor works, less cost, so that largely enlarged your pure profit.

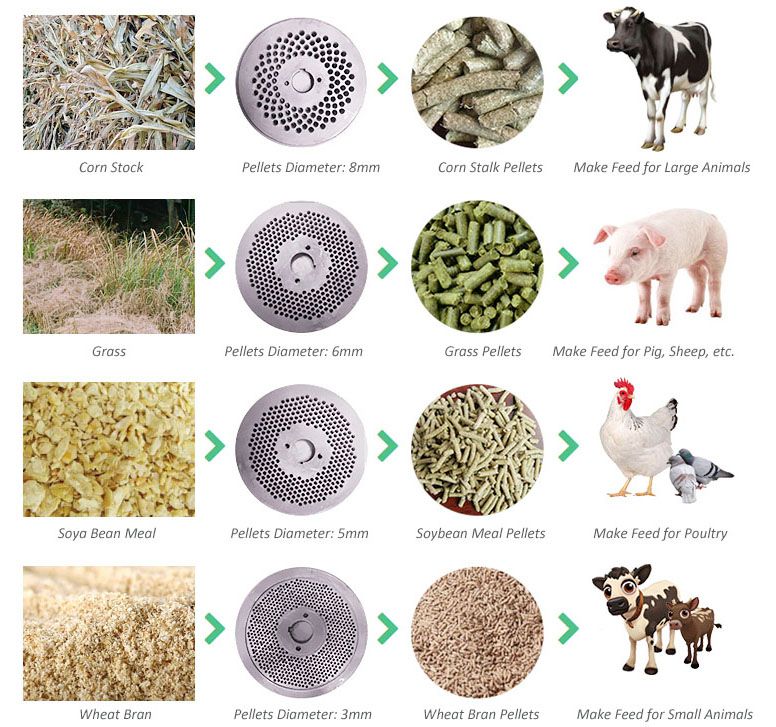

- Wide Application: Suitable for making feed pellets for different livestock, poultry animals.

Poultry / Animal Feed Pellet Making Process

Firstly, the feedstuff raw materials or feed ingredients such as soybean meal and maize will go through the crushing machine and be crushed into fine powder. Then, in the mixing equipment, the powder can be mixed with other materials such as vitamin, microelement, meal, bone, wheat bran etc. After mixing, they will become complete feed mesh. Then, the feed mesh will be sent to the animal feed pellet machine and be extruded into uniform pellets with desired diameter and length. After screening and cooling, the poultry feed pellets can be packed directly.

Figure 1 - Animal Feed Pellet Making Flow Chart

| 101 | Grinding Machine | 402 | Air Lock |

| 201 | Vertical Mixing Machine | 403 | Pellet Cooling Machine |

| 301 | Screw Conveyor | 404 | Vibrating Screen. |

| 302 | Temporary Storage Silo | 405 | Air Lock. |

| 303 | Screw Feeder | 406 | Cyclone Dust Collector. |

| 304 | Pellet Mill | 407 | Fan |

| 401 | Belt Conveyor | 501 | Electric Control Cabinet |

As shown in the Figure 1, the maize and soya bean meal (store & directly feed on ground) is sucked into the Grinding Machine 101 and crushed into fine powder. Any other powder/soft materials, such as wheat bran, bone meal, microelement, vitamin, etc, which don’t need to be crushed, they can directly feed into the Vertical Mixing Machine 201 from its feeding port. All materials are mixed uniformly and discharged into the hopper of Screw Conveyor 301 then feed into Temporary Storage Silo 302 by screw conveyor. By Screw Feeder 303, the mixed materials are uniformly and continuously feed into the animal feed pellet machine 304 then produced into feed pellets. The pellets are discharged into the hopper of Belt Conveyor 401 then feed into the Pellet Cooling Machine 403 through Air Lock 402. With the cooling process, the fresh & hot pellets are cooled, the pellet temperature is not more 5℃ than the room temperature. The cooled animal feed pellets are screened by the Vibrating Screen 404, then they can be packaged.

STLP Series poultry feed pellet making machine assembly unit is widely applied to small to medium scale of feed pellet production plant. If you are planning to set up a mini plant for making your own animal feed pellets on farm or start a small feed pellets manufacturing business, this small plant should be your best choice!

Equipment Details of the Small Poultry Feed Pellet Plant

The followings are brief introduction of each equipment included in this small feed mill plant. Don't hesitate to contact us if you have any questions or interested to get the detailed quotation!

-

Grinding Machine

9 FQ series of grinding machine is used to crush all kinds of feedstuff materials, such corn, broomcorn, wheat, beans, oil seed meal and other materials. It is widely used in small and medium feed production plant and small farms.

| Model | Power (Kw) | Capacity (kg/h) | Weight (kg) | Dimension (mm) |

| 9FQ510×125 | 7.5 | ≥600 | 122 | 955*800*1580 |

| 9FQ510×200 | 15 | ≥1000 | 170 | 965*840*1580 |

-

Vertical Mixing Machine

9HLP vertical mixing machine is used to mix all fodder materials together uniformly. It is the key equipment to guarantee the feed quality. This machine is widely used in small and medium animal feed pellet line. It can mix all kinds of feed materials according to the proportion.

| Type | Power (Kw) | Capacity (kg/h) | Weight (kg) | Dimension (mm) |

| 9HLP500 | 3 | 500 | 190 | 1500*1000*2440 |

| 9HLP1000 | 3 | 1000 | 230 | 1700*1260*2770 |

-

Animal Feed Pellet Mill

ZLSP 300 & ZLSP 400 pellet mill is the key equipment of this small feed mill plant. It can process powder materials like corns, oil seed meal & cakes, etc into feed pellets. Those feeds are widely used to feed livestock, poultry, fish, etc. This pellet mill is ideal choice for small and medium scale animal feed production line.

| Type | Matched power (Kw) | Capacity (kg/h) | Mainframe weight (kg) | Dimension (mm) |

| ZLSP300B | 22 | 600-800 | 350 | 1300*560*1100 |

| ZLSP400B | 30 | 800-1100 | 700 | 1600*640*1300 |

-

Pellet Cooling & Screening machine

KLN series counter flow type cooler is to cool down the fresh & hot pellets from feed pellet making machine. Pellets just extruded from animal feed pellet machine with 70-85℃, so the pellets need to be cooled till near room temperature to meet the storage requirement otherwise they will result in mildew.

It occupies small areas. It is convenient to transport and install and easy to dismount and adjust. The air consuming is low but the cooling efficiency is good.

| Type | Total power (Kw) | Capacity (kg/h) | Mainframe weight (kg) | Dimension (mm) |

| KLN1.0 | 5.5+3*0.75+0.2 | 2000 | 800 | 1096*1080*3033 |

You are welcome to contact us for more details about setting up a small feed pellet production line for cattle / poultry / livestock.

-

Hai... I'm Osman from Sabah, East Malaysia. Asking the price for small pellet machine suitable for chicken/quail feeding. My nearest port is Kota Kinabalu port. Post code 88000.

Thanks. -

What diameter pellet do you need, such as 2.5mm, 3mm, or more smaller, do you need crushed pellet for small chicken?

What capacity kg/h do you need for such plant? So that we give you detailed equipment list and cost for the plant. - I intent to used this machine to feed my small quail farm. Looking for 50kg/hr capacity with small size product ie. 2mm dia. pellet. My power supply is 220v.

-

You can choose the 120 model pellet mill for the quail farm, that is the smallest model we now do. And power is single phase, 220v, 50Hz.

The min diameterwe now do is 2.5mm, is that acceptable for you?