With the rapid development of aquaculture industry, the variety of aquaculture is increasing and the demands for floating pellet feed and sinking pellet feed is also increasing greatly. Accordingly, setting up an fish feed processing line has been regarded as a good way of getting rich at this moment. Fish, shrimp and other aquatic animals have small intestines and stomach, and poor digestion and absorption ability, so the processing technology of aquatic feed is much higher than that of livestock and poultry feed. (Related article: fish feed mill plant cost>>)

Sinking and Floating Fish Feed

To produce high quality fish feed, we must rely on scientific and reasonable processing technology and combine it with advanced, reliable and stable fish feed pellet machinery. Therefore, the selection of fish processing equipment is particularly critical. (Read more: Poultry Feed Mill Plant Cost >>)

ABC Machinery has been producing floating and sinking fish feed processing equipment for many years. As a formal fish feed pellet machinery manufacturer and supplier, the equipment produced by us is cost-effective and efficient. Customers who want to buy are welcome to visit our factory, and all our staff welcome you!

Buy Equipment for the Production of Floating and Sinking Fish Feed

Feed pellet extruding technology is mainly used in the production of special aquatic feed, pet feed and other animal feed. In addition to the advantages of the general animal pellet feed, the extruded fish feed pellet has its own outstandings:

- The extruded feed pellets can also improve the digestion and absorption rate of feeding animals, and effectively prevent animals from digestive tract diseases.

- Expanded feed can be applied to materials that contain starch and high fat content due to the starch gelatinization.

- What's more, the ripening of high temperature and high pressure also increases disinfection and sterilization. (Latest News: Floating Fish Feed Pellet Machine Exported to America >>)

Floating and Sinking Feed Mill Plant

It is because of so many advantages of feed extrusion that more and more commercial fish feed plants begin to adopt feed extruding equipment to produce sinking and floating fish feeds. Whether you plan to make fish feed for your fish pond or fishery, process the extruded fish feed pellets in your fish feed production factory, or start a fish feed making plant as business, we are always here for you!

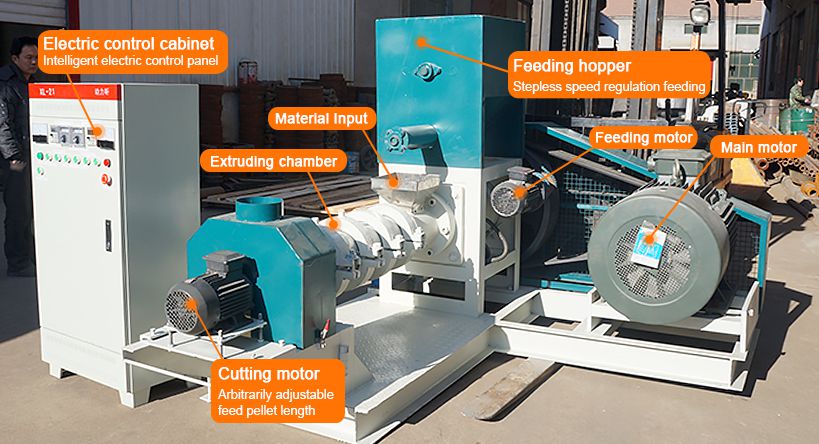

Fish Feed Pellet Extruder Machine for Sale

At present, most of the fish feed mills adopt feed extruder as the core equipment to produce floating and sinking feeds. The working principle of feed extruder is the powder materials that contains a certain amount of starch (more than 20%) are conditioned and treated by conditioner, and then the water content of the material can reach 25% ~ 27%, the temperature rises to 80℃ ~ 100℃.

Floating Sinking Fish Feed Pellet Machinery

The fish feed pellet extruder machine is composed of a feeding system, driving system, extrusion system, discharging mold and electrical control system.

The material with good tempering quality enters into the screw extrusion area. As the volume of the extrusion area becomes smaller along the axis, the pressure on the material increases gradually, and the compression ratio can reach 4 ~ 10. The material is extruded and pushed by screw, accompanied by strong shearing and friction action, the pressure and temperature rise sharply. Under the action of high temperature and high pressure, the starch in the material can be basically completely gelatinized, and the protein can be partially deformed.

Sinking Fish Feed Pellet in Extrusion

When the material is extruded out from the die under great pressure, due to the sudden leave and sudden enters into the atmosphere, temperature and pressure are decreased greatly, under the joint action of pressure and temperature difference, the volume of feed rapidly is expanded and the moisture is evaporated quickly, dehydration is set. Then, through the customized discharge model to form various shapes and structure, and the extruded feed is made successfully.

Floating and Sinking Fish Feed Extruder Machine Working Video

The above is the working video of our fish feed extruder machine in our fish feed production line. If you have any questions about the fish feed pellet production process , please feel free to contact us!

Setting up Fish Feed Plant to Make Sinking and Floating Feeds – Buy High Quality Fish Feed Pellet Machinery to Make Floating and Sinking Feed: HOT Sale sinking fish feed pellet machinery provided by fish feed pellet machine manufacturer or supplier, guide on process of floating and sinking fish feed production and how to start fish feed making business with limited cost in Tanzania, Egypt, Morocco, Ghana, South Korea, etc.

How to Choose Your Floating and Sinking Fish Feed Pellet Machine?

Quality is the life of an enterprise. In order to produce different kinds of floating and sinking fish feed with high quality, choosing the suitable equipment to set up a sinking fish feed processing line should based on your actual needs. Here are some tips to help you, and if you have no ideas about how to do it yet, please just contact us to get professional technical support!

Fish Feed Pellet Production Equipment Setup

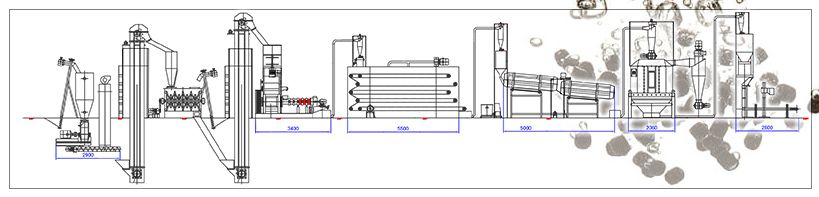

Small Fish Feed Pellet Plant Equipment Layout

To select suitable fish feed extrusion equipment, firstly you should understand how you plan to set up your fish feed pellet production factory which depends on the investment scale, fish feed production process layout, necessary factory building construction and other factors. But, in any case, you must be under the premise of ensuring the quality of the product, correctly and effectively select and use the fish feed production equipment. The following one is the sample of our small sinking fish feed production line setup, you can take it for reference.

Sample of 500KG/H Sinking Fish Feed Mill Equipment

| General Process | raw material crushing → mixing → extruding → drying → flavor → spraying → cooling → packaging |

|---|---|

| Main Equipment | Screw Conveyor, Bucket Elevator, Pulverizer, Pulse Dust Collector, Mixing machine, Vertical Mixer, Pneumatic Conveying System, Dryer, Spraying machine, Feed Extruder, Cooler, Automatic Weighing and Packing Machine, Electrical Control System, etc. |

Customized Fish Feed Production Line Setup Display

ABC Machinery, the TOP fish feed pellet machinery manufacturer, always provides customers with the premium quality equipment, formulation, installation and market news based on the actual condition and the requirements of the customers. If you are interested in setting up a small fish feed pellet plant to produce both sinking and floating feed, just get in touch with us to get the latest price list and parameters!

Characteristics of Fish Sinking and Floating Feed

To select the suitable production equipment of aquatic feed, you also need to understand the characteristics of fish feed and aquatic feed, which will make your fish feed production easier.

Make Fish Sinking and Floating Feed Pellet

Due to the short digestive tract and related physiological characteristics of aquatic animals, in order to speed up digestion and absorption, the size of aquatic feeds should be smaller than that of livestock and poultry feeds. For example, the size of eel and prawn feeds should reach 80 to 120 meshes.

The protein content of livestock and poultry feed is generally less than 20%, but the protein content of aquatic animal feed is mostly 30% ~ 40%, the protein content of eel feed is as high as 65% ~ 70%.

The feed for fish and other aquatic animals should have high adhesion and water resistance.

Some raw materials need to be treated aseptic, the equipment selected is easy to clean and less residue, especially in the production of shrimp and eel feed, other kinds of feed shall not be produced at the same time to prevent cross contamination.

- For the extruded fish feed pellets, how much moisture, how much moisture after drying?

- The final extruded fish feed pellets have a moisture of about 18%, after drying, the moisture reaches 8%-10%.

- What is the difference between horizontal mixing and vertical mixing?

- Horizontal has a smaller model, partial wood chips of raw materials recommended horizontal. Vertical minimum model 500, cereal feed materials more vertical.

- Customers who add cooking oil in the pellet feed extruder machine set, from where to add?

- Generally from the spray barrel to add pet feed, you can add the right amount in the mixing section, but fish and shrimp feed is recommended to add only from the spray.