The following are common accessory equipment work with biomass pelleting machine. View the below words to have a brief understanding of these machines. For different biomass raw materials, the pellet production process flow is also different. So, not all these accessories are nacessary. It depends on your raw mateiral (kind, size, moisture content...)

If you are not sure which accessory machine is need for your pellet plant, feel free to get in touch with us, tell us your specific situation, cost budget and other requirements and our professinal salesman will be glad to give you advice!

Wood Debarking Machine

A complete wood pelleting plant requires a debarking machine. The wood debarking machine is an efficient equipment that eases and hastens the log debarking process. This awesome device can be classified into two diverse models according to the distinct wood diameter and the different types of wood logs that they process. The featured models include the single roller debarking machine and the twin roller debarking machine.

Twin Roller Debarking Machine

The valuable equipment is recommended for paper mills, paper pulps and wood storage and forestry farms. It is also important in the production of medium-density fibrous board, wood chipping and veneer rotary-cutting. This machine can be used to debark broad-leaved wood and coniferous wood. The proclaimed peeling rate of specific species of wood such as the eucalyptus and poplar is at least 95%. It can partially be utilized to debark frozen and dried wood.

For any biomass pelleting plant that requires wood logs in their operations, they should gladly consider the godsend twin roller debarking machine.

Wood Chipper

Nature provides wood in form of massive trees with irregular and asymmetrical forms. The wood chipper comes to solve this grave issue. The wood chipper is a machine that processes and converts the massive branches and wood blocks of diverse sizes into mere simple wood chips. This machine is an excellent wood equipment for processes preceding the actual wood treatment processes in biomass pelleting plant. It's widely used in paper mills, production of particle board and fiber board, various industrial processes and in the stock preparation section in the wood manufacturing plant.

Hammer Mill

Our machine while coupled up with another hammer mill is capable of ultimate fulfillment of the great demands of the crucial pulverization. The machine is equipped with abrasion resistant liner that offers abrasion resistance attributes in the crushing chamber. This simple machine stamps increase in yield and ensures stable performance in the industrial process. Our machine features an elegant design which confirms less space occupation. It also saves energy in the plan thus cost reduction.

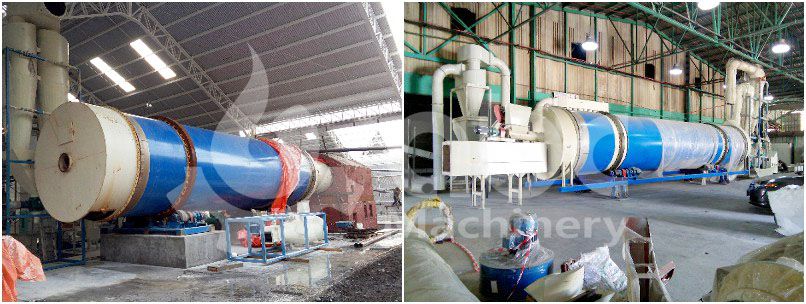

Drum Dryer

Water is important however its presence in certain materials such as wood for a considerable length of time may result to poor quality or complete damage of the wood. The drum dryer saves the wood from the harmful wet state. It has the ability to handling the large quantity of raw materials present in any paper mill or any industry. It is characterized of features that post proper flow in the industrial processes which include stability, flexibility and adaptability. The machine is widely used in the fields of metallurgy, chemistry, agriculture, building materials and in the pellet plants.

Due to the aforementioned attributes, the drum dryer is the ultimate add-on for ring die wood pelleting machine in large size biomass pellet plants.

Cooler

Process including natural processes in a healthy human body emits heat. Industrial processes produces heat at harmful and fatal rate hence the application of the much needed cooler. The cooler is indispensable in the pellet production section of industrial processes. It can reduce temperatures to the extreme range of 70C-90C to just 3C-4C above the ambient temperature. The reverse-flow cooler consumes less energy while providing adequate water moisture for efficient pellet transportation storage.

Note: Here is a great tip to ensure cost saving in a pellet plant that produces lower yield per hour compared to the other pellet plants in competition. The pellet plants will require an integrated cooler. An integrated pellets cooler contains the cooler and a sieve. This equipment offers great advantages that include increase in work efficiency and reduction in cost. The ABC machinery can offer this awesome machine to the required industries. The sieve is usually positioned under the cooling chamber. Pellets and other granule products are sieved after they are passed through the cooler. The sieve issued is a new metallic net that easily renewed with low maintenance costs.

Pellets Bagging Maching

Consumers' first impression is generated from their view of the packaging of the product. Every large scale pellet plant requires a pellets bagging machine that will ensure uniform and fast packing of the products. ABC Machinery has the ability to offer the pellets bagging machine to meet the demands of the large scale factory. It is packing machine driven by pneumatic power. The pressure value of 0.5MPa can be used.