As the demand for diverse animal feed ingredients continues to grow, copra meals have emerged as a highly efficient feed material. Due to their rich nutritional content, copra meals are now widely used in the animal feed production sector and have attracted growing attention from animal feed processing plants. This article will comprehensively explain the nutritional value of copra meals, the types of animals that benefit from them, and detail how to make animal feed using copra meals efficiently. Additionally, it will explore how feed factories can use copra meals to reduce costs while maximizing productivity.

Nutritional Value and Versatile Applications of Copra Meals

Copra meals are a high-value feed ingredient, packed with fiber, protein, fats, and minerals, which greatly enhance the overall quality of animal feed.

Basic Composition and Nutritional Profile

Copra meal is a powdery material made from dried and ground coconut meat. While the exact composition varies slightly depending on the source, a typical copra meal contains:

| Component | Content Range | Function |

|---|---|---|

|

Protein |

5%-10% |

Supplies essential amino acids, supports animal growth |

|

Minerals |

High (Calcium, Magnesium, Phosphorus) |

Strengthens bones and immune system |

|

Fat |

2%-5% |

Provides energy for physiological activities |

|

Fiber |

High |

Aids digestion, especially beneficial for ruminants and poultry |

What Animals Benefit from Copra Meal-Based Animal Feed?

Thanks to its rich nutritional profile, copra meal feed supports the dietary needs of multiple animals, boosting growth rates, overall health, and feed conversion ratios. It is especially suitable for:

Ruminants (Cattle, Sheep, Deer)

-

High-fiber content (30-40%) improves rumen function, facilitating better fiber breakdown and digestion, while enhancing feed efficiency by up to 20% and boosting overall animal feed production line productivity in feed mill process systems.

Poultry (Chickens, Ducks, Geese)

-

Protein and fats provide ample energy, contributing to healthy weight and feather quality, while minerals such as calcium enhance eggshell hardness and egg quality, supporting poultry in automatic poultry feed machine operations.

Swine (Pigs)

-

Fiber stimulates gut motility, maintaining digestive system health, while enhancing nutrient absorption by 25–30% and increasing the efficiency of the animal feed pellet production line.

Rabbits

-

Crude fiber improves gut health by preventing constipation and digestive issues, while boosting satiety, curbing overeating, and maintaining intestinal balance in animal feed processing routines.

Aquatic Animals (Fish, Shrimp)

-

High protein promotes muscle growth and healthy development, while rich minerals enhance immunity, reduce disease risk by 10–15%, and improve farming outcomes in the animal feed milling industry.

Which Animals Benefit From Animal Feed Using Copra Meals

In summary, using copra meals in animal feed significantly improves nutritional value and supports the profitability of high-quality feed milling plant operations. ABC Machinery, with its advanced technology and reliable animal feed machinery, offers full solutions to the challenge of how to make animal feed using copra meals, helping feed producers implement a successful animal feed production business plan.Free consultation, get the full range of production support you need!

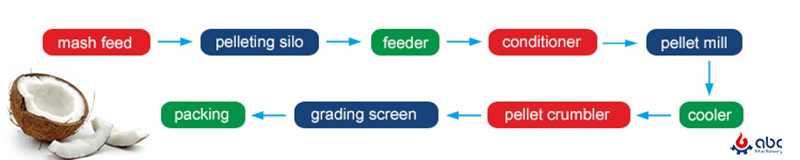

How to Make Animal Feed Using Copra Meals: Step-by-Step Process

Copra meals must go through several key processing stages to be transformed into high-quality animal feed pellets:

Grinding(1–3 mm):

-

Copra meal is blended with other feed materials and ground using an animal feed crusher machine, achieving a fine particle size of 1–3 mm.

-

ABC Machinery’s efficient grinders ensure over 95% material uniformity, enhancing pellet formation and reducing waste.

Mixing and Conditioning(Moisture: 15–20%, Temp: 60–80°C):

-

Moisture content is adjusted to 15–20%, and mixed using an animal feed mixing machine under controlled temperatures (60–80°C).

-

ABC Machinery’s intelligent mixing systems accurately control humidity, temperature, and time, maximizing nutrient balance and feed efficiency.

Pelletizing and Cooling(Pressure: 40–60 MPa, Cooling: 80–90°C to ~5°C):

-

Mixture is compressed into durable pellets under 40–60 MPa, then cooled from 80–90°C to ambient temperature (~5°C).

-

ABC Machinery’s pellet machines feature high-efficiency cooling systems, ensuring pellet durability and consistent output across the animal feed processing plant.

Copra Meals Feed Process Flow Chart

Build an efficient Copra Feed Production Plant with ABC Machinery

As the feed sector grows, ABC Machinery offers end-to-end services from design to installation. We support clients in mastering how to make animal feed using copra meals, ensuring low-cost, high-efficiency execution of their animal feed business plan.

Customized Design Boosts 30% Efficiency

-

Tailored animal feed milling machine configurations boost productivity by 30%, supporting production from 1 to 50 tons per hour.

-

Intelligent layout reduces raw material waste and maximizes processing output.

25% Higher ROI Through Cost Optimization

-

ABC Machinery provides detailed investment guidance to control expenses and improve ROI by over 25%.

-

Energy-saving animal feed processing equipment cuts power use by 15% annually, enabling animal feed mill long-term low-cost operations.

15% Labor Cost Reduction with Automation

-

Fully automated systems, including the animal food making machine, minimize manual labor and cut labor costs by 15%

-

With downtime reduced by over 300 hours annually, and a machine failure rate as low as 0.5%, your animal feed mill remains highly efficient and reliable.

24/7 Technical Support for Smooth Setup

-

ABC Machinery provides full support from selecting the right animal feed machine to installing and commissioning your feed pellet production line.

-

Our 24/7 support ensures seamless operations and rapid response for all animal feed milling machine needs.

Animal Feed Manufacturing Plant for Sale

Copra meal is a cost-effective and nutritious raw material. With scientific processing and the right equipment selection, feed producers can solve the challenge of how to make animal feed using copra meals while reducing animal feed plant costs and improving operational efficiency. As a trusted supplier in the feed industry, ABC Machinery brings deep experience and cutting-edge technology to every project. Unsure where to start? Contact us now for a free consultation!