In the global animal feed market, where intelligent and customized production trends are on the rise, corn-based animal feed stands out for its high energy value and cost-effectiveness. This article will thoroughly explore the role of corn in the animal feed production process and feed production line, detailing how to make animal feed from corn/maize with standardized production techniques, optimal animal feed processing equipment, and strategies for maximizing nutritional output. Whether you're a small-scale farmer or planning a full-scale animal feed processing plant, this guide will help you build a high-efficiency, cost-effective corn feed facility.

How to Make Animal Feed From Corn/Maize at Low Cost?

Why Corn/Maize Becomes the Ideal Raw Material for High-Quality Animal Feed Pellets?

Corn contains over 60% starch and is rich in protein, fat, fiber, and minerals, making it a core ingredient in various animal feed pellets. Understanding how to make animal feed from corn/maize centers on scientifically leveraging corn’s high energy to meet the nutritional needs of pigs, chickens, animals, and cattle, significantly improving farming efficiency and animal growth rate.

-

Corn starch content reaches 60–70%, providing crucial energy for pigs, chickens, animals, and cattle, improving daily weight gain by 10–15%.

-

Whether ground into fine powder, extruded into pellets, or mixed with other nutrients, corn adapts perfectly to different feed production line technologies.

-

Corn contains protein (7–9%), fat (3–5%), fiber (2–3%), and vitamins A, B complex, and E, forming a solid nutritional base for feed formulations.

Corn Usage in Different Animal Feeds

Different farm animals require varying corn ratios and animal feed manufacturing processing methods. Proper matching maximizes corn’s nutritional advantages while catering to animals’ digestion and growth traits.

|

Animal Type |

Corn Ratio (in Feed) |

Recommended Processing Method |

|---|---|---|

|

Pigs, Chickens |

50%–65% |

Grinding + Mixing + Pelleting |

|

Animals |

25%–45% |

Micronizing + Mixing + Extrusion |

|

Cattle, Sheep |

30%–50% |

Coarse grinding + Mixing or Pelleting |

Explaining Different Type of Animal Feed From Corn/Maize

Each animal species has distinct requirements for corn particle size and processing method, so selecting the right animal feed making process equipment is crucial. Whether you’re a small-scale farmer, a feed mill, or an industrial investor, we tailor solutions based on your budget, production capacity, and raw materials like corn or soybean meal. Contact us anytime for free expert advice from our engineers, available 24/7.

Step-by-Step Guide: How to Make Animal Feed from Corn/Maize

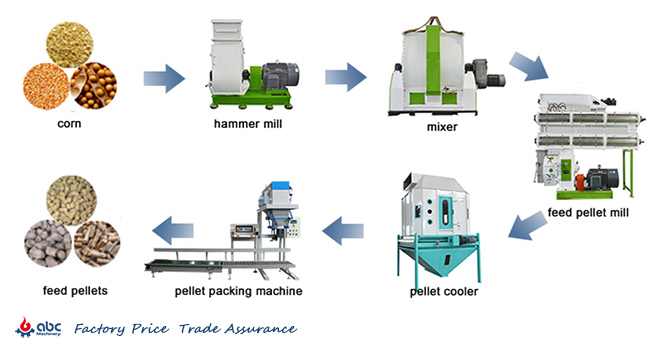

Mastering how to make animal feed from corn/maize requires following scientific, standardized animal feed production process steps: raw material cleaning, particle size control during grinding, precise mixing, pelleting or extrusion, cooling, and packaging. Every step influences animal feed processing plant final feed quality. ABC Machinery provides professional guidance for your animal feed production plan.

35% Efficiency Improvement in Raw Material Cleaning

-

Corn must have ≥99% impurity removal rate and ≤0.2% impurities to avoid clogging animal feed production machines and ensure quality stability.

-

Our automatic impurity removal system improves cleaning efficiency by 35%, reducing feed line impurity content to below 0.1%, protecting animal feed processing machine from wear and contamination.

±3% Particle Size Control in Grinding

-

Ideal particle sizes: pigs/chickens 0.8–1.2 mm, animals (micronized) 0.15–0.3 mm, cattle/sheep 2.5–3.5 mm, improving digestibility by 15–20%.

-

ABC Machinery’s animal feed grinder machine offers 5 adjustable size settings with ±3% accuracy, increasing feed utilization by 12%.

±0.15% Accuracy in Mixing

-

Nutrient mixing error must be ≤±0.3%; otherwise, feeding rate drops 8–10%.

-

Our intelligent mixer ensures 99.7% homogeneity with only ±0.15% error, improving feed quality and animal immunity.

97% Pellet Formation Rate with Pelleting or Extrusion

-

Low-quality pellets have <85% formation rate, causing nutrient loss; our lines achieve >95% pellet formation.

-

Our animal feed pelleting machine maintains precise temperature control to preserve protein activity, boosting digestion and absorption by about 15%.

30% Improvement in Cooling and Packaging Efficiency

-

Rapid cooling lowers moisture to ≤5%, with packaging sealing rate ≥99% to guarantee storage quality.

-

Our cooling system boosts efficiency by 30%, packaging sealing reaches 99.5%, and intelligent storage reduces spoilage by 20%.

Animal Feed From Corn/Maize Manufacturing Process Flow Chart

Build a Corn-Based Animal Feed Production Plant with ABC Machinery!

ABC Machinery offers complete animal feed processing machine from corn raw material to finished animal feed products, suitable for pigs, chickens, animals, and cattle. From small to large capacity, we help you build a dedicated feed production line for self-sufficiency, cost reduction, and profit maximization!

Our Advantages Include:

-

Over 20 years’ experience in animal feed manufacturing machine production and automation control, serving customers worldwide.

-

Customizable solutions based on corn moisture, particle size, nutrition targets, and animal species—covering grinding, mixing, pelleting, and extrusion.

-

Multilingual technical support and remote video debugging; installation cycles compressed to 7 days in many countries.

-

Lifetime technical support plus rapid spare parts replacement, ensuring worry-free operation of your animal feed processing plant.

-

Flexible payment and financing options including L/C, T/T, and installments for low-barrier investment in your feed mill plant.

-

Energy efficiency optimized by up to 28%, outperforming traditional equipment, shortening your animal feed mill plant payback period.

Successful Wood Pellet Plant Project for Sale

Choosing advanced animal feed processing equipment and scientific feed pellet production line design ensures your corn-based feed’s nutrition is fully unlocked, helping farmers maximize economic benefits. ABC Machinery’s experience and technology build your exclusive corn animal feed production line, achieving high quality and efficiency. Contact us now for customized solutions, detailed quotes, and professional feed formula guidance!