With the rapid global surge in demand for clean energy, large-scale industrial wood pelletizing plant projects are experiencing unprecedented growth opportunities. However, challenges such as insufficient capacity of biomass pellet production lines, excessive energy consumption, and instability of wood pellet manufacturing equipment have become bottlenecks restricting the further development of wood pellet manufacturing plants. Against this backdrop, selecting a set of efficient, stable, and intelligent biomass pelletizing equipment is key for large-scale biomass pellet factories to enhance competitiveness and achieve sustainable development.

Start Your Pellet Production Project for Biofuel Business

Start Your Pellet Production Project for Biofuel Business

Three Key Preparations Before Constructing a Wood Pelletizing Plant

According to the International Energy Agency (IEA) 2023 report, the global biomass energy production annual growth rate has reached 6.8%, and the market demand for industrial biomass pelleting will surpass 700 million tons per year by 2030. Scientific preliminary preparation is the foundation of success before building a large industrial wood pelletizing plant. The following is a Biomass Pellet Production Guide:

Factory Location Saving Over 30% of Wod Pelletizing Plant Transportation Costs

An ideal pellet plant location should consider these factors:

-

Proximity to raw material sources such as sawdust, bark, and crop stalks not only significantly saves over 30% of biomass pellet production line transportation costs but also reduces the carbon footprint;

-

Location with industrial electricity subsidies or access to renewable energy (e.g., biomass cogeneration) will significantly reduce unit production costs for wood pellet manufacturing equipment manufacturers;

-

Convenient transportation, close to ports or railway hubs, lowers transportation costs for wood pellet manufacturing equipment manufacturers by approximately 10-15%;

-

Being far from residential areas and compliant with the "Industrial Enterprise Boundary Noise Standard" (GB12348) facilitates smooth environmental approval for wood pellet manufacturing equipment manufacturers.

Improve Over 40% Efficiency by Scientific Raw Material Selection

Different raw materials vary significantly in physical structure, chemical composition, moisture content, and calorific value, directly affecting crushing difficulty, pelletizing efficiency, and pellet quality. Below is a brief comparison of common raw materials:

|

Raw Material |

Moisture (%) |

Fiber Structure |

Characteristics and Treatment Suggestions |

|---|---|---|---|

|

Sawdust / Wood Chips |

20–45 |

Stable structure |

Suitable for standard pellet mills; high output; low dust |

|

Corn Stalks |

35–60 |

Large pores |

High silica content causes wear; use wear-resistant dies and specialized crushing systems |

|

Rice Husk |

10–20 |

Brittle |

High dust; low pellet compression rate; control particle size to improve density |

|

Palm Empty Fruit Bunch (EFB) |

40–70 |

Sticky, long fibers |

Requires specialized EFB crushing + drying + conditioning system |

Raw Materials for Biomass Pellet Manufacturing for Sale

Raw Materials for Biomass Pellet Manufacturing for Sale

Below 30 mg/Nm³ of Controlling Wood Pellet Plant Emission Concentrations

With increasingly stringent environmental regulations, eco-friendliness is not only a prerequisite for project initiation but also crucial for the long-term reputation and export qualifications of wood pellet production line manufacturers:

-

EU ENplus A1 standard mandates particulate emissions not exceeding 30 mg/Nm³ throughout the biomass pellet production process;

-

China's environmental assessment "Pollutant Discharge Permit Management Measures (Trial)" requires wood pelletizing plants producing over 100,000 tons annually to install VOCs treatment biomass wood pellet machine to ensure odor and dust compliance;

-

The US EPA standard requires wood pellet plant noise levels below 65 dB (daytime) and 55 dB (nighttime).

Due to differences in raw material composition, moisture content, fiber structure, and local emission policies, generic wood pellet machine design often fail to achieve stable capacity or pass environmental approvals smoothly. If you want to reduce the trial-and-error costs of your biomass pellet production line at the early planning stage, ensuring your biomass pellet machine plant matches raw materials perfectly and meets environmental standards in one go, please contact ABC Machinery. We provide free consultation to help you take the right first step faster.

Main Equipment for Large Industrial Pellet Plants

A modern large wood pelletizing plant requires a systematic combination of equipment and intelligent layout to guarantee continuous operation and product quality. A standard large pellet production line usually includes the following processes: raw material receiving → preliminary crushing → drying → fine crushing → conveying → batching → pelletizing → cooling → screening → packaging → finished product storage. Core equipment mainly includes:

Crushing System (Hammer Mill)

-

Handles raw materials with moisture from 10% to 55%, adaptable to sawdust, stalks, palm empty fruit bunches, etc.

-

Crushing particle size controllable between 3–8 mm to ensure pellet density,Magnetic separation protection to prevent iron particles entering the machine.

-

Raw material switching time under 15 minutes, significantly saving cleaning and adjustment time,Continuous operation 1000 hours with over 99% no-failure rate.

-

ABC Machinery’s multi-stage crushing module improves crushing efficiency by 30% and reduces the entire wood pellet feed line’s electricity consumption by 12%.

Drying Equipment (Rotary Drum Dryer)

-

Capable of drying high-moisture raw materials up to 60%, stabilizing outlet moisture at 12–15%;

-

Thermal efficiency over 85%, using waste heat recovery and intelligent temperature control,Durable drum with wear tolerance ±0.5 mm.Exhaust dust removal efficiency up to 99.5%, meeting ENplus A1 standards (emission ≤ 30 mg/Nm³);

-

Shell temperature control protection ensuring operational safety at high temperature.ABC Machinery supports remote monitoring and adjustment of drying stage temperature, controllable between 110–180°C.

Pelletizing Equipment (Ring Die Pellet Mill)

-

As the “heart” of the entire biomass pellet production line, the biomass pelletizing machine determines final pellet combustion performance and market value.

-

Uses ring die structure with die diameters ranging from 520 to 850 mm,Forming rate stable ≥98%, breakage rate <2%, and consistent output;Supports switching pellet diameters among 6mm, 8mm, and 10mm, meeting ENplus A1 and DINplus standards,Intelligent die temperature control at 75–95°C to avoid carbonization or powdering.

-

Single machine capacity 2–5 tons/hour, capable of parallel operation to build 100,000+ ton/year systems,Automatic lubrication and overload protection systems ensuring average no-failure continuous operation over 720 hours;

-

Core bearings use imported SKF parts with precision error ±0.1 mm,Overall machine failure rate below 0.8%, significantly reducing downtime losses.

Cooling and Screening System (Counterflow Cooler + Vibrating Screener)

-

Pellet outlet temperature 70–90°C, cooled pellets at room temperature ≤40°C,Multi-stage counterflow cooling increases efficiency by 30%;

-

Screening system removes over 98% of broken pellets and powder, ensuring uniform appearance and calorific value;

-

Entire line noise controlled at 60–65 dB, well below EPA and domestic standards,ABC can optionally install negative pressure dust removal systems linked with environmental modules.

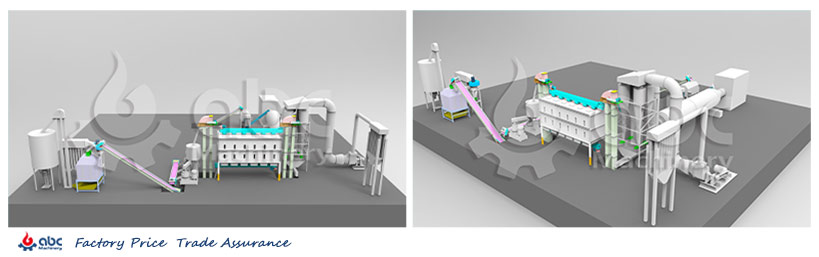

Profitable Biomass Feed Pellet Plant for Sale

Profitable Biomass Feed Pellet Plant for Sale

ABC Machinery Solutions and Advantages in Wood Pelletizing Plant

ABC Machinery offers full lifecycle service support, empowering clients from design to after-sales:

- Wood pellet plant project design cycle as short as 3–4 weeks, supporting simultaneous output of drawings and 3D production line simulation;

- Equipment installation and commissioning 15 days to 6 weeks depending on project scale;

- less than 40 hours of on-site training, operation manuals, and remote support;

- Domestic clients receive 24-hour on-site response, international clients 48–72 hours remote technical support;

- Supports global remote diagnostic systems for real-time equipment operation and alert monitoring;

- Entire system energy savings of 15–22%, potentially saving millions in annual electricity costs;

- The whole system qualifies for green low-carbon demonstration project subsidies, with ABC assisting certification and application.

Modern Automatic Wood Pellet Feed Mill for Sale

Modern Automatic Wood Pellet Feed Mill for Sale

With the expanding biomass energy market, the construction of large industrial pellet plants is timely. However, only with scientific early planning, high-quality equipment, and reliable partners can you stay competitive in this fiercely contested market. ABC Machinery commits to providing professional technology, comprehensive services, and advanced equipment to help you build a high-capacity, high-efficiency, and low-energy-consumption large biomass pellet manufacturing plant, achieving both green development and commercial success. Contact us now for a free project evaluation and equipment quotation!