In simple terms, pelletizing is a process that allows you to convert waste materials to solid fuel. This allows individuals to use pellets for thermal combustion. Wood pellets are considered to be the most common products for pelletizing.

Wood pellets can be easily manufactured from all kinds of agricultural forestry waste, such as sugarcane bagasse, peanut shells, sawdust, caster shells, paddy straw, cotton stalks, sunflower stalks, mustard stalks, tobacco waste, bamboo dust, jute waste, tea waste, palm husks, wheat straw, coconut residues, soybean husks, forestry waste and more.

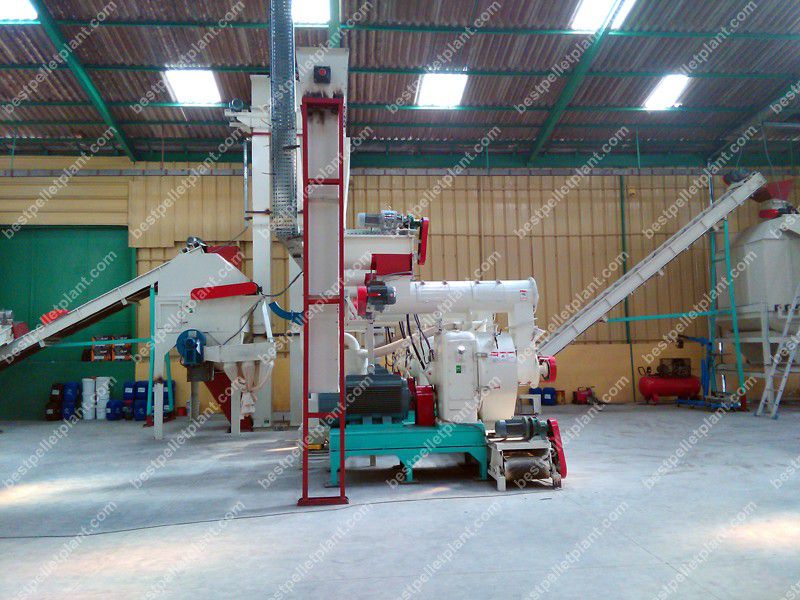

Successful Projects of Wood Pellet Production Line

Factors that Affect The Output of Pellet Line

- Raw Material

- Mixing of Fine Fiber Content and Coarse Fiber Content

It's important to understand that every material comes with different features and offers varied performance. The perfect combination of fine fiber content and coarse fiber content is an ideal choice to get excellent result from pelletizing.

- Moisture Content of Raw Material

- Particle Size of Crushed Machine

- Compression Ratio

First of all, you need to understand the basic concept related to compression ratio. In simple terms, compression ratio is considered to be quite close to the ring die pellet mill. Compression ratio refers to the actual diameter or lengths of ring die holes. In theory, when the compression ratio is more, the output of the pellet plant is better. One drawback of compression ratio is that the discharging speed may be low and the holes may be easily blocked.

Needless to say, the output of a pellet plant also depends on an operator's skill and experience. The operator should properly adjust the machine according to moisture content, room temperature, changes in temperature, particle size, formula and other considerations.