As global demand for animal protein continues to rise and feed ingredient supply chains face increasing pressure, animal feed manufacturers are being challenged by rising production costs, limited capacity, and the need for process upgrades. In this context, how to make pellet feed using by-products like oil cakes and oil meals has become a focal point. These ingredients, when processed with efficient and eco-friendly animal feed milling equipment, offer a low-cost and high-quality solution for animal feed mill plant.This article explores the nutritional and economic value differences between oil cakes and oil meals, and presents ABC Machinery's professional solutions for designing an advanced feed pellet production line. This guidance can help build a scalable and sustainable animal feed processing plant.

Start Your Making Pellet Feed With Oil Cakes Business

Oil Cakes vs Oil Meals: Nutritional Differences and Economic Value

Oil cakes and oil meals are by-products of vegetable oil extraction and serve as economical, protein-rich feed ingredients. Using them effectively can reduce animal feed manufacturing costs by 10% to 30%, while significantly improving animal growth and feed conversion ratios.

|

Category |

Oil Cake |

Oil Meal |

|---|---|---|

|

Production Process |

Mechanically pressed |

Pressed + Solvent-extracted |

|

Fat Content |

5%~10% (varies) |

<1% |

|

Crude Protein |

35%~45% |

40%~50% |

|

Suitability |

Suitable for livestock, needs blending |

Nutritionally balanced for various species |

|

Common Types |

Peanut cake, cottonseed cake, rapeseed cake |

Soybean meal, sunflower meal, cotton meal |

Economic Value of Making Animal Feeds from Oil Cakes and Meals

- Compared to fish meal or full-fat soybean, oil meals reduce ingredient cost by 20% to 40%.

- <1% oil content significantly reduces animal feed processing equipment wear and improves mold life by over 25%.

- Palatability improves after pelletizing, with intake rates increasing 8% to 15% and growth cycles shortened by 5 to 10 days.

- Stable pellet form resists breakage, making it ideal for long-distance transport and commercial packaging.

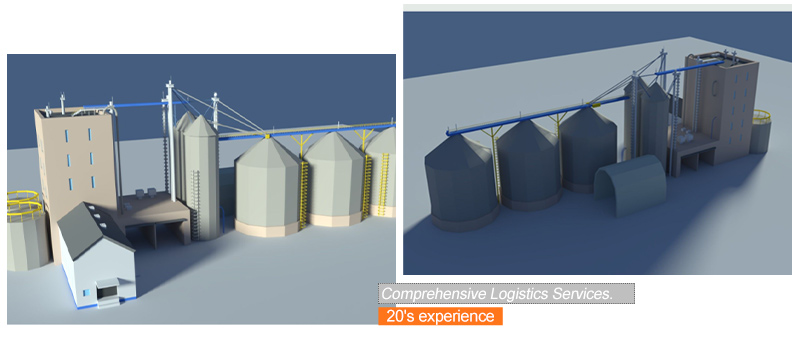

3D Drawing of Animal Feed Manufacturing Mill Price

If you're unsure about how to formulate or design the right animal feed manufacturing process, especially using oil-rich by-products, contact our experts. We offer free ingredient evaluation and customized feed pellet formulas.

Planning a High-Efficiency Feed Pellet Production Line Using Oil Cakes and Meals

With over 20 years of experience in animal feed production, ABC Machinery recommends a four-module design approach covering ingredient adaptation, process layout, automation, and environmental controls.

Ingredient-Specific Processing for Pellet Quality

-

High-oil cakes: (e.g., peanut, tea seed) use cold-drying and dual conditioning to retain nutrients and control oil leakage under 2.5%.

-

High-fiber meals: (e.g., cotton, rapeseed) apply dual hammer mills and vortex classifiers, improving uniformity by 18%~22%.

-

Tannin/anti-nutrient meals: add adsorption and moist-heat conditioning to lower inhibitor residues.

-

ABC Machinery provides raw material testing and mold customization for precise animal feed pellet press compression matching.

Modular Line Design for Scalable Expansion

-

Integrated compact systems: A 3-in-1 crushing-conditioning-pelleting machine reduces startup time by 35% with one operator.

-

Standardized functional units: Conditioning adjusts for 12%~30% moisture via adaptive thermal curves.

-

Flexible scalability: Add coating, spraying, sieving, or animal feed packaging machine units as needed.

-

Cost-efficient expansion: Modular growth saves 20%~30% on reinvestment and operations versus full-line builds.

Smart Control Systems for Transparent Production Management

Pellet feed production demands high physical and batch consistency. Our smart factory solution includes:

-

Auto collection of key data: feed ratios, temperature/humidity, compression rates, moisture, with +/-3% fluctuation.

-

Real-time alerts: abnormal discharge temp (>85°C), oil adhesion, motor overload.

-

Remote visual control: ERP/MES system integration for centralized coordination and energy monitoring.

-

Batch tracking: Each batch’s thermal path and forming data are recorded for quality assurance and formula optimization.

Sustainable and Safe Feed Manufacturing

-

Heat recovery: Captures >75°C heat with up to 22% efficiency.

-

Multi-stage dust removal: Cyclone + bag filter + activated carbon keeps emissions <20mg/m³.

-

VOC control: Oil vapor condensation units manage emissions during peanut cake processing.

-

Noise and energy standards: IE3/IE4 motors keep noise <78dB for legal and export compliance.

Profitable Animal Feed Pellet Making Line for Sale

ABC Machinery: Your Long-Term Partner in How to Make Pellet Feed

ABC Machinery isn't just a supplier of animal feed pelleting machine or animal feed machinery—we're your strategic partner in turning oil cake and meal into market-ready, high-efficiency feed pellets. We offer end-to-end services: from ingredient testing and formula design to complete line delivery.

Our Advantages:

-

Switch between raw materials in under 15 minutes using a global supply network.

-

24-hour after-sales response time ensures minimal downtime.

-

Pellet dust levels conform to national <20mg/m³ standards.

-

Multilingual customer service for global reach.

-

Flexible financing options to reduce investment burden.

-

Feed Conversion Ratio (FCR) optimized to below 1.5 for better livestock performance.

-

Shared customer success cases to help improve your animal feed business plan success rate.

Buy Animal Feed Processing Plant at Low Cost

Whether you're looking to scale your animal feed making business, train staff in animal feed manufacturing training, or explore innovative ways on how to make animal feed using copra meals, how to make animal feed from maize cobs, or even how to make animal feed forager, ABC Machinery provides unmatched value. Get in touch with our engineers today to start animal feed processing plant business in how to make pellet feed using cost-effective oil cake and meal resources.