Fish feed pellets are fed to different species of fish to meet their nutritional requirement for healthy growth and development. A fish feed pellet mill production line has multiple parts that all work together towards a mutual goal of producing good quality fish pellets. (Read more: Fish Feed Plant Project Report >>)

Make Fish Feed Pellets for Business

ABC Machinery is one of the best fish feed mill machinery suppliers in China, offering the turkey solution of fish feed pellet production plant projects, from the fish feed production process design to fish feed pellet milling equipment manufacturing and construction. Welcome to contact us to get more information about the fish feed production and fish feed machine price now!

Benefits to Setup A Fish Feed Mill Plant

For those who know that fish farming is growing worldwide and people needs fish feed for the fish farming business, building a feed mill factory for fish to provide superior and quality pellets in the market is a good choice. There are numerous benefits of establishing a fish feed mill plant. Such as:

- You can produce fish feed pellets of any type according to your requirements.

- Quantity and quality of pellets can be controlled as per your needs.

- The fish feed mill plant cost can be greatly reduced.

- It can also used to make feed pellets for livestock and poultry. (Related post: Small Chicken Feed Pellet Making Machine for Sale >>)

- You can also process the fish feed pellets for sale in your local place.

2 TPH Fish feed Pellet Production Line Setup Cost

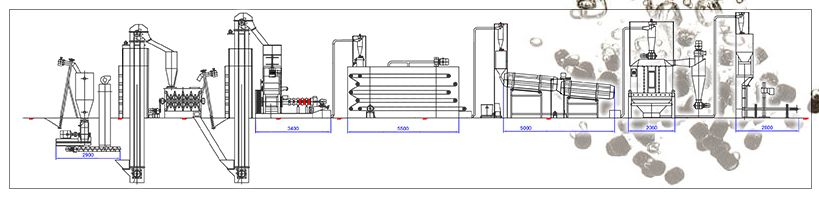

The 2 tons per day fish feed pellet mill plant provided by ABC Machinery can be equipped with fish feed pellet making machine, crusher, mixer, feeder, belt conveyor, cooling machine, packaging machine and more. If you are interested in, just contact us directly to get more details!

In this fish feed processing plant, this fish feed pellet machine can be two sets of 1tph small pellet mill or one set of 2tph ring die pellet mill. The design can be adjusted flexibly according to your investment cost.

Custmized Fish Feed Mill Plant Design

The cost to set up a fish feed pellets manufacturing plant is closely related to the equipment selected. To choose the most suitable fish feed processing machines, it is better to know all your requirements and conditions, like the raw materials, the approximate ratio of raw materials, plant size, transformer capacity, pellets diameter and output requirements, etc.

We will offer customized plan of equipment selection based on your raw materials, factory and power supply. Generally, our technical engineers will provide flow chart of a commercial feed mill equipment. Welcome to send us more details about your requirements on fish feed pellet processing plant setup!

2TPH Fish Feed Mill Plant Setup Cost – Buy High Quality Feed Pellet Machine for Fish Feed Making: HOT sale 2 tons per hour fish feed mill plant offered by feed pellet machine manufacturer or supplier, guide on process of fish feed pellet production and how to start fish feed pellet making business with limited cost in Tanzania, Egypt, Morocco, Ghana, South Korea, etc.

Production Process of 2TPH Fish Feed Mill Plant

The basic overview and idea of the fish feed pellet milling process is given step-by-step below.

Fish Feed Pellet Production Process

- Grinding the Raw Material

The raw material must be crushed before it is made available for pelleting. The electric feed hammer mill and diesel feed hammer mill are two common hammer mill machine for sale that are generally used for this purpose. They crush large-sized raw material into fine particles.

- Mixing to Distribute Raw Material Evenly

A mixer must be used to make sure that every component of the raw material is mixed efficiently. A horizontal ribbon feed mixer is one of the commonly used animal nutrition feed mixing and processing equipment in this industry. You can load a large amount of material in it and get it mixed well.

- Making Pellets of Different Sizes

The feed pellet machine for sale for fish feed can be typical animal feed pellet mill and feed extruding machine. And feed pellet mill is for sinking fish feed or fish bait, and extruder machine is for floating fish feed or slow sinking fish feed. Choose which type of fish feed pellet making machine should be based on your actual needs!

Produced Fish Feed Pellet With Different Sizes

And price of these two types fish feed pellet machine are totally different. Fish feed extruder machine is normally expensive than typical feed pellet mill machine.

- Drying Fish Feed Pellets

A dryer is used to remove extra water content from the pellets. Mesh belt pellet dryer is a common dryer in which hot air is used to dry pellets.

- Reducing Temperature of Pellets

A cooler is used to reduce the temperature of pellets that were initially dried with the help of hot air.

- Packing and Storing Fish Feed Pellets

The fish feed packing machine weighs the pellets automatically and sends them into the storage bags of appropriate size.

| Stage of fish (carps) | Particle and pellet size |

|---|---|

| Spawn | <50-80 mm particle |

| Fry | 0.5 mm dia. of crumbled dry feed pellet |

| Fingerlings (3-4g) | Crumbles of 1.5-2 mm dia. |

| Growers | 2.5-3 mm dia dry pellet |

NOTE: The above is our general fish feed pellet production process design, we also provide customization service, mainly including process design, factory building and equipment construction which are based on your actual condition and your requirements for fish feed production. (Read more: cattle feed business plan>>)

Whether you would like to make fish feed for your fish individual fishery, or processing fish feed for sale, or starting fish feed production as a business, we are always here to help you to solve the question when you plan to set up a fish feed production plant, warmly welcome to contact us!

Small Fish Feed Pellets Production Line for Sale

Here is the video of extruded floating fish feed pellets by our fish feed pellet making machinery. If you have any idea of setting up one fish feed plant to make floating and sinking feed pellets, please contact us for more information!

- How to determine the compression ratio if I do chicken feed?

- It depends on the customer's raw material recipe, usually do chicken feed using 3mm or 4mm aperture ring die, 32 ring die machine grinder recommended so configuration: 3mm - 1:6.5, 1:7 each; 4mm - 1:7, 1:8 each It basically meets most of the chicken feed recipes.

- What is the life span of the ring die parts of the feed pellet mill in this production line?

- The life of a ring die for feed is 600-800 hours under normal use; the pressure roller is 200-300 hours