As environmental awareness and clean energy policies continue to grow, the biomass pellet fuel market is experiencing significant momentum. More and more wood pellet making machine manufacturers and entrepreneurs are showing interest in building their own wood pellet plant, thus advancing the green energy industry. This article focuses on pellet plant design, providing beginners with a comprehensive guide to the entire design process and key considerations to scientifically plan and efficiently build their plant, maximizing investment returns.

Start Your Best Wood Pellet Plant Business

Four Key Preparations Before Designing a Pellet Plant

Early-stage planning is critical for ensuring efficient production, energy conservation, and sustainable profitability. Scientific pellet plant design at this stage can shorten construction periods by 15–25% and reduce biomass pellet production plant operational costs by more than 20% (China Circular Economy Association, 2023).

Three Essential Raw Material Parameters

- Common materials: straw, sawdust, rice husk, bamboo shavings, and palm shells with moisture content ≤ 12% and fiber length between 50–100 mm.

- Equipment compatibility: Moisture content determines whether a drying system is needed; high-hardness materials require a ring die wood pellet machine.

- Recommendations: Pre-sample and test materials for moisture deviation ±0.5% and particle size error ≤ ±1 mm to ensure compatibility with wood pellet production machine and production efficiency.

Raw Material for Wood Pellet Making Manufacturing

Set Production Targets and Daily Output

- A new biomass pelletizing plant should determine daily output based on market demand and available funds.

- Output directly impacts wood pellet manufacturing equipment model and configuration, serving as the primary basis for wood pellet plant layout by wood pellet plant suppliers.

Keep Equipment Budget Within 70% of Total Cost

- Equipment investment: Biomass wood pellet manufacturing equipment typically accounts for 60–70% of total investment. Aim for failure rates ≤1% and dust removal efficiency >99%.

- Standards: Emission levels must meet GB/T 18810-2002; wood pellet making equipment noise ≤65 dB.

- Structural advice: Choose modular quick-assembly structures for wood pelleting plant with 85% spare parts interchangeability, shortening installation to 7–10 days.

Factory Location and Infrastructure Requirements

- Choose a location with good transportation, steady power supply, raw material availability, and required environmental permits.

- Safety standards: Ground load capacity ≥5 t/m², moisture-proof elevation 300 mm, fire spacing ≥5 m.

- Environmental emissions: Particle emissions ≤ 10 mg/m³ (in biomass pellet line with national standards).

Due to the vast variation in project goals, budgets, and raw materials, we can't detail every situation here. If you're evaluating project feasibility or already planning, feel free to contact ABC Machinery for free material testing, biomass pellet production line design, and investment analysis to help you plan efficiently and avoid pitfalls.

Core Elements of Pellet Plant Design

A high-efficiency biomass pellet mill plant relies on well-structured processes, properly selected wood pellet machinery, the right automation level, and optimal logistics within the factory. Here are four core design principles:

Six Key Steps of Wood Pellet Production Process:

- Standard pellet plant design includes:

- Raw material pretreatment: Remove metal, stones, and control moisture between 8–12%.

- Crushing: Use hammer mills to reduce particle size to 3–5 mm.

- Mixing: Blend different materials for consistent calorific value.

- Pelletizing: The core process with ring die pellet machines operating at 115–130°C, with >95% forming rate.

- Cooling: Cool pellets to room temp (25–30°C) to prevent breakage.

- Packing: Automated systems with ±0.5% weight deviation.

- ABC Machinery provides complete energy-saving process designs to help reduce energy use by over 10%.

Energy-Efficient wood pellet processing equipment Selection

- Crusher: Chromium alloy hammers; optional screen for wet materials.

- Pellet machine: High-pressure ring die + alloy rollers; continuous operation 16–24 hours.

- Cooling: Counter-flow air cooling lowers breakage to <3%.

- Packing: With auto-alignment and vacuum sealing; >98% daily uptime.

- ABC Machinery smart control system responds within 0.5 seconds, improving energy efficiency by 12%.

Automation and Staffing Strategy

- Closed-loop control of feeding, temperature, cooling, and weighing.

- Standard crew: 1 operator + 1 technician + 1 quality inspector per shift.

- Training: 3–5 days, minimum 24 hours.

- ABC Machinery offers comprehensive training, ensuring wood pellet machine failure rate <2%.

Factory Logistics and Storage Layout

- Raw material zone: Upwind area with ≥5 m fire spacing, forklift access.

- Finished product zone: Temperature <35°C and humidity <60% to prevent moisture absorption.

- Aisle width: ≥4 m to accommodate two-way transport.

- Smart logistics design improves efficiency by over 15%.

- ABC Machinery creates optimal storage/logistics systems for greater ROI.

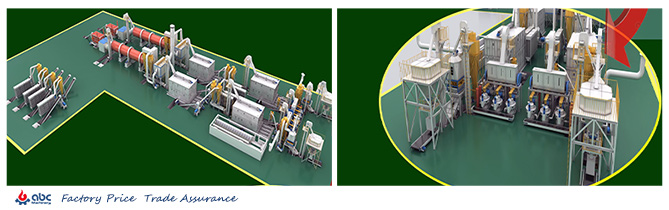

3D-Drawings of Wood Pellet Manufacturing Plant for Sale

Why Smart Clients Choose ABC Machinery for Pellet Plant Design

In the biomass fuel industry, pellet plant design defines success. You may think design is just drawing flow charts or selecting machines, but real design is the architecture of an efficient, low-cost, and stable system. ABC Machinery delivers this system:

- One-stop solution: Even beginners can quickly build a complete wood pellet plant.

- 99% customer satisfaction, with successful projects worldwide.

- We don’t just sell machines; we build stable, profitable systems with 18+ hours continuous runtime and annual maintenance cost as low as 0.5%.

- 24/7 support: Response time under 2 hours, global spare parts shipped within 7 days.

- Beyond equipment: ROI analysis reports included with every project.

Setup Best Wood Pellet Manufacturing Plant for Sale

When selecting a partner, don’t just compare quotes. Choose an integrated wood pellet manufacturing plant provider offering design, wood pellet processing equipment, and service together. This reduces communication and construction risk significantly.Take action now! Contact ABC Machinery for your custom pellet plant design. Our engineers are available 24/7 for free consultation to ensure your factory doesn’t just get built, it turns a profit.