With the promotion of global clean energy policy, wood pellets are more and more widely used as alternative fuel in Pellet Stove. Whether you are building a new biomass pellet fuel plant or upgrading an existing production line, choosing the right pellet mill pelletizing equipment and planning a reasonable production line design is the key to the success of the project. In this article, we will focus on the common misconceptions in the process of biomass pellet production plant construction, equipment selection techniques and technology trends to help investors build an efficient and sustainable wood pellet production system.

Choose Profitable Pellet Maker for Pellet Stove at Low Price

Three Common Misconceptions When Choosing a Pellet Maker for Pellet Stove

When selecting a dedicated pellet maker for pellet stove, many wood pellet equipment manufacturers are misled by superficial factors like “universality,” “low price,” and “simple operation,” overlooking the strict requirements that fuel pellets impose on wood pellet manufacturing equipment performance and production processes. According to the Global Biomass Energy Market Report (2024), the demand for high-quality fuel pellets grows at 12% annually, making correct wood pellet making equipment choice crucial.

Misconception 1: All Pellet Makers Can Produce Stove Fuel Pellets

-

Not all biomass pellet makers are suitable for fuel pellets!

-

Fuel pellets require strict standards for density (≥1.2 g/cm³), diameter (6mm or 8mm), and moisture content (≤10%).

-

Only specialized biomass pellet equipment, utilizing scientific biomass pellet processing technology, can ensure dense, hard pellets that avoid looseness and combustion efficiency reduction.

Misconception 2: Pellets Can Be Used Immediately After Pressing

-

Pellets must be cooled and dried before use!

-

Newly pressed pellets can reach temperatures over 80℃ and contain higher moisture.

-

Cooling and drying are necessary—use specialized biomass pellet coolers or allow natural air-drying for 12-24 hours to prevent pellet breakage and stove blockage.

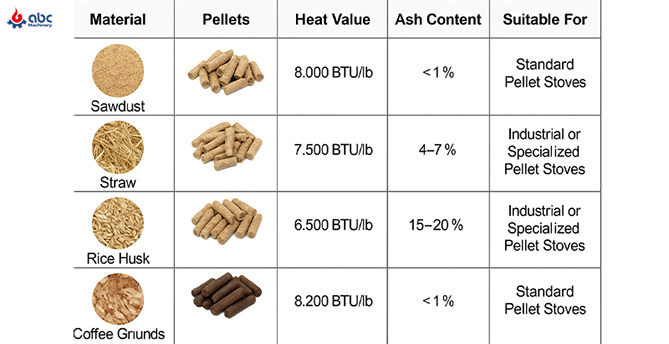

Misconception 3: Raw Materials Can Be Any Wood Scrap

-

Only pollution-free, untreated wood materials are suitable!

-

Wood containing paint, glue, or chemicals releases harmful gases when burned, posing health risks.

-

It is recommended to use safe raw materials meeting the GB/T 28732-2012 pellet fuel standards, such as untreated sawdust, wood chips, and bamboo shavings—standards adopted by most professional wood pellet manufacturing plants.

Choose Suitable Pellet Maker for Pellet Stove

Due to significant differences in pellet types, usage environments, and biomass pellet making equipment parameters, this article covers only typical misconceptions and cannot address all details or case studies. For more information about biomass pellet processing technology, selecting wood pellet production line manufacturers, or project construction plans, please contact ABC Machinery for free customized advice and technical support.

Technological Upgrades of Modern Pellet Maker for Pellet Stove

With the widespread application of biomass energy, pellet stove fuel quality requirements continue to rise. Unlike earlier simple-structured, manually operated pellet machines, modern biomass pellet equipment is undergoing significant technological upgrades towards high efficiency, intelligent automation, and low maintenance.

99% Qualified Output Rate! Automation Becomes Mainstream

-

Modern pellet machines typically feature PLC control systems for automatic feeding, temperature control, pressing, and cooling linkage. Users operate the entire wood pellet manufacturing line with a touchscreen interface.

-

ABC Machinery’s intelligent system automatically adjusts parameters for different raw materials, enabling even beginners to operate easily, reducing labor dependency, and ensuring a stable output with a 99%+ qualification rate.

15% Longer Combustion: High-Pressure Die + Variable Frequency Drive

-

Using a high-pressure die structure combined with spindle variable frequency technology, the wood pellet maker machine handles various hardwoods, bamboo chips, straw, and other materials, producing pellets with density ≥1.2 g/cm³ and combustion duration extended by 15% compared to traditional pellets.

-

ABC Machinery offers customized dies to ensure dense, uniform fuel pellets meeting domestic and international stove combustion standards, improving combustion efficiency by 10%-15%.

Noise ≤65dB, Energy Consumption Reduced by 20%: Ideal for Homes and Small Factories

-

New-generation machines optimize transmission structures and sound insulation, cutting energy consumption by about 20%, with noise controlled under international residential standards (≤65dB), suitable for residential areas and community factories.

-

ABC Machinery’s noise reduction meets residential use standards, equipped with energy-saving motors and temperature-controlled shutdown functions, aligning with green and user-friendly needs.

Save 30% Space: All-in-One Multifunctional Machines Popular

-

Market-available pellet maker all in one units integrate crushing, mixing, pelletizing, and cooling, perfect for medium-output, space-constrained small factories.

-

ABC Machinery’s one-stop solutions enable rapid production startup, highly efficient equipment linkage, saving at least 30% of floor space and 20% of operation & maintenance time.

3-Minute Quick-Disassembly Structure, 85% Parts Compatibility

-

Most modern pellet machines adopt quick-disassembly rollers and die structures, simplifying maintenance. Even ordinary operators can replace parts independently, minimizing downtime.

-

ABC Machinery provides modular core components with global parts delivery within 3-7 days. Spare parts have 85% interchangeability, significantly reducing downtime risks and ensuring continuous production.

Complete Wood Pellet Production Line for Sale

ABC Machinery: Your Trusted Pellet Maker and Complete Line Supplier

When selecting wood pellet plant suppliers or constructing a fuel pellet production line, the equipment itself is important, but a reliable biomass pellet plant manufacturers often determines project success. ABC Machinery is not only a pellet equipment manufacturer but also a full-line solution provider and long-term global partner.

-

Free customized selection plans for capacities from 1 to 30 tons/hour, improving project startup efficiency by 25%.

-

Equipment certified with ISO 9001, CE, UL, exported worldwide.

-

Multilingual support, remote response within ≤2 hours, 98% problem resolution rate.

-

Modular spare parts design with 85% parts interchangeability, reducing maintenance wood pellet plant costs by 15%.

-

ROI investment analysis provided; energy consumption lowered by 30%, operating costs reduced by 18%.

-

30 hours of operational training plus 24/7 after-sales service; customer satisfaction rate exceeds 95%.

Biomass Pellet Production Plant for Sale

Whether you are an individual user, factory operator, or planning to establish a biomass pellet plant or a complete wood pellet production line for sale, ABC Machinery offers one-stop support from raw material preprocessing to finished product packaging, including biomass pellet production line design, installation, and after-sales service. Contact us anytime for free sample demonstrations, detailed equipment information, and customized quotes!