In recent years, as environmental protection and energy issues become increasingly pressing, small pellet plant solutions—especially devices like homemade pellet machine and homemade pellet mill—have rapidly emerged as the top choice for small-scale users and rural entrepreneurs. A mini pellet plant is not only cost-effective and easy to operate, but also highly flexible and compatible with a wide range of raw materials.

Choose Best Homemade Pellet Machine for Sale

Choose Best Homemade Pellet Machine for Sale

How to Choose the Right Raw Materials for a Pellet Plant?

Thanks to their flexibility and low operational costs, home-based small pellet plant setups are becoming increasingly popular in rural business ventures. Compact equipment such as the small pellet mill machine or mini pellet press enables users to carry out a full pelleting process with minimal setup, often requiring only basic grinding and drying steps. Many first-time users start with a homemade pellet making machine, which saves budget and helps quickly test suitable raw material parameters.

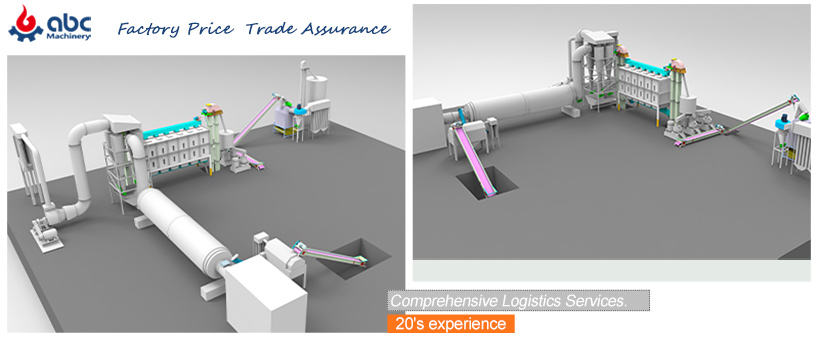

Wood Feed Pellet Manufacturing Plant Design

Wood Feed Pellet Manufacturing Plant Design

Raw Material Types and Compatibility

Home-use pellet systems support a wide range of materials, including:

- Powdered Materials: Corn flour, soybean meal, etc. According to the China Biomass Pellet Industry Report, about 25% of small pellet plants use powder-based feedstock, which offers easy operation and high efficiency.

- Wood-Based Materials: Sawdust, wood shavings, etc., require crushing to 2–5mm in particle size to smoothly pass through pellet machines. These account for approximately 40% of the materials used in biomass pellet plant setups, primarily for fuel pellet production.

- High-Moisture Materials: Grass, wet rice husks, etc., must be dried if their moisture content exceeds 15%. The ideal range is 12%-14%; too much moisture may cause pelletizer blockages or jams.

Moisture and Particle Size Control

- Moisture Content: Directly affects pellet forming quality. The optimal range is 12%-15%. Moisture levels above 20% can reduce pelletizing efficiency by 25%-30%.

- Particle Size: Must be under 5mm. Oversized particles may damage or jam the machinery.

Since raw materials vary greatly in moisture and granularity, there’s no one-size-fits-all solution. ABC Machinery is committed to helping you identify the most suitable pretreatment approach to ensure seamless production. If you have questions or need guidance with material handling or pellet production, our engineers are available 24/7 for free consultation.

Build a Home-Based Mini Pellet Plant: Process and Equipment Overview

Home-based pellet production is quickly becoming a new income-generating option for rural entrepreneurship. According to the 2023 China Biomass Pellet Processing Report, such setups account for 61.7% of all pellet plants nationwide due to their low investment, low risk, and ease of use.

Raw Material Pretreatment

The first step in pellet processing is pretreatment, ensuring ideal condition for pelletizing. Required Equipment: Small crusher + basic drying device

- Crushing: Materials like corn cobs, sawdust, and rice husks must be crushed to below 5mm.

- Recommended Equipment: ABC Machinery’s mini pellet machine or homemade pellet making machine, featuring high-efficiency air delivery systems and four-level motor protection, designed for continuous 3-hour operation.

- Drying: Most materials have high initial moisture content that hinders pellet formation.

- ABC Machinery offers intelligent temperature-controlled dryers, which reduce drying time to approximately 40 minutes and ensure consistent pellet plant design quality.

Pelletizing (Turning Biomass into Pellets)

- Flat Die or Ring Die Pellet Machine: Ideal for home use, with low energy consumption and easy operation. Standard die sizes are 6mm, customizable to 8mm or 10mm for different applications.

- ABC’s mini pellet mill achieves a 98% forming rate. Users seeking higher output can opt for mini ring die pellet mill or small ring die pellet mill, which offer faster pelletizing speed and higher density—perfect for mid- to high-end users.

Cooling and Screening (Final Step to Improve Pellet Quality)

- Cooling: Can use natural air cooling (30 minutes) or fan-assisted cooling (15 minutes).

- ABC Machinery’s systems feature auto-adjusting airflow suited to seasonal and material changes.

- Screening: ABC’s dual-layer stainless-steel screening machines separate fine powder and finished pellets efficiently, achieving a 96% success rate and a breakage rate under 3%, enhancing final product value.

Wood Feed Processing Equipment in Production Line

Wood Feed Processing Equipment in Production Line

Five Reasons to Choose ABC Machinery to Start Your Homemade Pellet Business

- Pellet machines designed for home-based production ranging from 300kg/h to 1000kg/h with flexible power options (electric/diesel/gasoline)

- Free plant layout and installation videos provided; even beginners can launch in under three days

- High pellet forming rate of 98%, compatible with over ten types of agricultural and forestry waste

- Direct-from-factory pricing saves over 15%, with a standard 1-year warranty and lifetime technical guidance

- Trusted by global clients in multiple countries/regions with a 95% satisfaction rate; virtual factory tours available

ABC also provides a “72-hour rapid response + lifetime tech support” service commitment. In addition to a comprehensive product system and robust service, ABC Machinery emphasizes real-world operability. Choosing our mini pellet plant means accessing end-to-end support—from pellet plant design, layout planning, and production to operational optimization. Whether you need to buy mini pellet mill or create a full pellet plant layout, our team of experienced pellet plant manufacturers and pellet plant suppliers is ready to help you establish a sound wood pellet plant business plan and achieve rapid deployment.We also offer mobile solutions like mobile pellet plant and portable biomass pellet plant, ideal for users in remote areas requiring flexible deployment.

Wood Feed Pellet Pellet Making Line for Sale

Wood Feed Pellet Pellet Making Line for Sale

With the right equipment configuration and process design, you can effectively utilize local resources and reduce production costs. If you're planning a high-performance, cost-effective mini pellet plant, ABC Machinery is your reliable partner. From mini pellet press and small mobile pellet plant to complete small pellet production line systems, we ensure comprehensive operational support from equipment selection to profitable pellet production.For free consultation, please contact us anytime.