Leaf is a standout amongst the most well-known things in our life. You may take it futile more often than not, or even feel irritated to manage the various fallen leaves in the fall and winter. However, with a leaf pellet process, this pointless thing can be swung to biomass pellets to be blazed effectively. We are offering factory-price wood pellet manufacturing equipment to make pellet from leaves. (Related article: wood pellet making machine price>>)

Make Pellets from Leaves

-

Winter-fuel cost has for some time been an extraordinary number of costs for most families, while it might be not all that effective to smolder for conventional energizes. How to get modest and powerful energy? Presently, before the next winter comes, people have found the raw material for the cost-effective energy ---leaf to assume a critical part in decreasing your financial plan for powers. Leaves have the favorable position that they don't require a folio. Sawdust needs a cover including cornstarch works, and there are fluid items available. The warmth of pressure causes the lignin in the leaves to serve as a binder. The points of interest of making your own pellets.

Hot Sale Mini Wood/Leaf Pellet Maker for Home Users

Small Wood Pellet Mill Display

Homemade Leaves Pellet Making Machinery on Hot Sale

Mini Pellet Mill for Sale mainly refers to the flat die pellet mill machine which is divided into two type including die rotating type and roller rotating type. In order to meet the different condition and requirements from our customers from different countries and regions, our R&D team has designed and developed into different types pellet making mills equipped with different driving powers.

| Types | Driving power | Suitable Condition |

|---|---|---|

| Die rotating type | Electric engine | Common home use, farm use with electric generator. |

| Gasoline engine | The place where the electricity cost is high and not easy to connect electricity. | |

| Diesel engine | ||

| PTO (driven by tractor) | Farm without electric generator, or far away from the power generator. | |

| Roller rotating type | Electric engine | It can pelletize both soft and hard raw materials. |

| Diesel engine |

The above are the features of single mini homemade leaves pellet maker, and we also offer the leaf pellet making line equipped with a series related machinery together to make higher quality leaf pellets. Feel free to contact us for more information!

Small Biomass Pellet Manufacturing Unit Overview

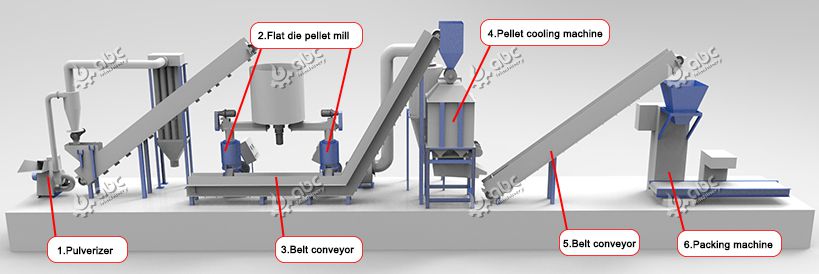

3D Flow Chart for Small Biomass Pellet Manufacturing Plant

Real Shot of Small Biofuel Pellet Making Machinery Line In Factory

With a series of machinery, the main leaves pellet making process includes crushing step, drying step, pelletizing step, and packing step. And this process can be added or reduced based on the requirement and actual condition. If you are interested in starting a leaves pellet manufacturing business with a limited budget, the small pellet making unit should be your best choice for its following advantages:

- Small size, easy operation and maintenance, flexible process, less space occupied.

- Factory price of related equipment, low labor cost, low energy cost.

- High automation, continuous production, high efficiency.

All of them make this small pellet making unit a hot sale for many years around the world. Feel free to contact us for more details of this pelletizing unit and we are always at your services!

-

Leaf pellet plant manufactured by ABC Machinery is for making natural matter to pellets. It is little and versatile for you to move it unreservedly. Equipped with cutting edge innovation and great quality, it can prepare pellets proficiently and gainfully. To facilitate the operation, this leaf pellet plant receives the level pass on configuration. When it works, the primary segments rollers and bite the dust will be rushed to deliver an extraordinary compel and push crude material to the gaps on the bite the dust. At that point you can get your leaf pellets.

Video of Small Scale Wood Pellet Making Process

Here is the running video of our small wood pellet maker machine in the wood pellet making line, if you have any problem, you can contact us for free!

Highlights to Make Pellets from Leaves

Materials Flexibility ---- Ready-to-get Raw Materials

Biomass Raw Materials for Wood Pellet Fuel Making

Except of the leaves, there are numerous sorts of biomass materials can be used for making pellets through the wood pellet maker mill, including corn straws, wheat stalks, cotton stalks, switchgrass, horse feed, nut soybean shell, rice husk, espresso husk, bamboo and other delicate products can be pelletized. And you can get the Inexhaustible raw materials with low investment, because the biomass raw materials are accessible locally, maintainable and renewable. (Related article: how to pelletize hops>>)

Good for the Environmental Protection

These days, the origin of "low-carbon life" is established in a great many people's hearts. Accordingly, more and more families are attempting to make their own pellets fuel with a wood pellet making machine to cut on spending on stove and home cooking and heating. (Read more: straw pellet machine for sale>>)

Making Leaf Pellets with Cost-Effective Wood Pellet Making Mill

-

Pellets are renewable assets, so they offer a much greener arrangement than blazing non-renewable powers like oil, coal or gas. Biofuels is carbon-impartial that means it will not produce bad gas to the air. It is confirmed that the utilization of wood pellet fuel results in the end of 75% carbon discharges that would be created by fossil fuel warming.

-

You cannot just make pellets from leaves to decrease the living cost, but also do your part for the earth, too. While you will require packs of pellets, you won't need to store vast piles of cleaved wood. Keep bounty available with the goal that you don't run out on a cold night and address the issues of little creatures.

Wide Applications of Final Produced Leaf Pellets

-

Making pellets for smoldering: Pellets are renewable vitality for housewarming in stove blazing.

-

Making creatures sustain pellets: Pellets for Domesticated animals, poultry, aquatics, etc. With blending and cooking preparation, the food pellets are anything but difficult to process and nourishing. (Related article: cattle feed business plan>>)

-

Making pellets for bedding administration: Making bedding material intended to address the issues of today's equine, family domesticated animals and little creature raisers. It is a perfect thought for creature and poultry reproducing in grain sustain production line, animal ranch, poultry ranch, and singular agriculturists, bolster handling industry, and so forth.

Buy factory price pellet making machine from pellet making machine manufacturer or supplier, learn to process pellets from leaves, get FREE guidance to setup leaves pellet making machine projects for business in Thailand, United Kingdom, Chile, Russia, New Zealand, Canada etc., at low cost.