Making Crop Straws Pellets with Pellet Press Machine

“Make Wastes Profitable” is becoming a hot topic in recent years. From this point of view, crop straw can be applied to bio-fuel pellet production. Straw pellets have the advantages of renewable, emission-reduction, low pollution and economical. Besides, it is very easy to make straw into fuel pellets, even for individuals. With a small straw pellet mill, you can make small scale straw pellets for warming on the farm or at home by yourself. Biomass straw pellet fuel is much superior to conventional energy like coal. (Related article: how much does a pellet mill cost>>)

Wheat Straws, Rice Straws and Millet Straws

Unlike fossil fuel, the straw resources are endless as the plant grows. Straw can be burned directly, but it is difficult to use, store and transport because of big volume and low weight. After being pressed by a biomass pellet machine, smooth and density straw pellets will be made. Straw pellets can be stored for a very long time and they are clean and convenient to use and transport. (Read more: turn leaves into fuel pellets>>)

Produced Straw Pellets by Straw Pellet Production Line

Building Straw Pellet Production Line / Pellet Plant

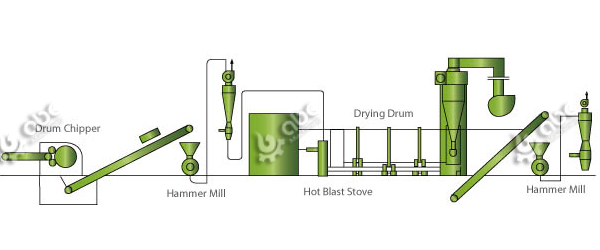

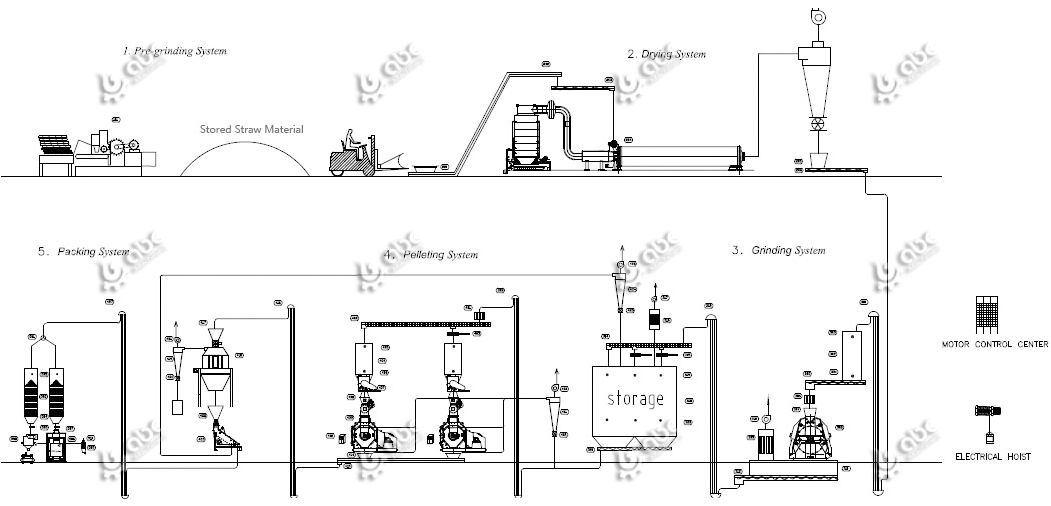

Straw pellet making line realizes the straw pellet production through a series of process and machinery.

| Main Process | Necessary Machinery | Description |

|---|---|---|

| Crushing | Hammer mill/crusher | In this process, the raw material is crushed into small size less than 3mm to meet the inlet requirement of the following process |

| Drying | Dryer | Dryer is equipped to adjust the moisture content of the crop straws to 12%-14% |

| Pelletizing | Pellet press machine | Pellet making machine is the key part of the straw pellet production process, needing more attention during the whole straw pellet produciton. |

| Cooling | Cooler | With the high pressure and temperature inside the pellet making machine, the freshly produced straw pellets need to be cooled for later packing |

| Packing | Packer | Packer is divided into manual packer and automatic packer, you can choose one based on your condition and requirements |

This production process is our general straw pellet production process, and usually GEMCO Pellet Plant Supplier offers comprehensive and customized pellet making solutions based on your specific raw material conditions and requirements.(Learn more: wood pellet machine factory>>)

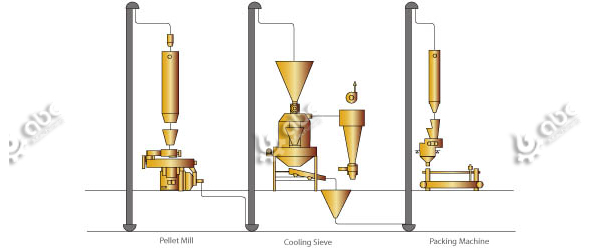

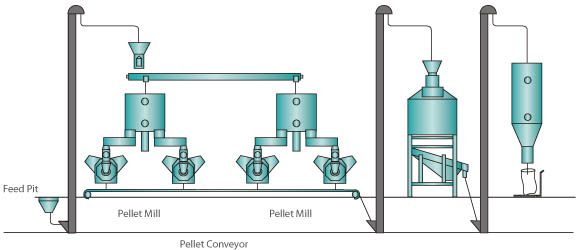

Straw Pellet Production Plants Display

Below are some of the pellet production business plants we have designed for our customers.

In order to start the straw pellet production successfully, you should pay more attention to the key process---- pelletizing process, in which the straw pellet making machine plays a very important role. The below is our hot sale straw pellet press machines with factory-price, you can contact us for more information!

Straw Pellet Press Machine for Sale

Straw pellet press is designed for making green fuel pellets from crop straw. The reason why straw pellet mills are so popular is that the feedstock resource is easy to get, abundant and cheap. According to the different requirement in the production capacity, our straw pellet making equipment is generally divided into two types including small scale and large volume pelleting line, and the output decides the output of the whole production line. (Learn more:how to pelletize hops>>)

Flat Die Pellet Mill for Small Scale Straw Pellet Production

Ring Die Pellet Press for Large Scale Straw Pellet Production

With the pellet press machinery, the final pelletized straw pellet has the following features:

- High efficiency

- Low cost

- Wide application

- Renewable

- Eco-friendly

- Promote the development of biomass energy

- Promote the popularization of straw pellet press.

Replacing conventional coal with straw pellets can save 20% of coal resources and reduce 65% of sulphur emission. According to the present annual industrial coal consumption, it saved 6400-7200, 00000 ton coal per year and reduced 360, 0000 ton sulphur emission. GEMCO is a professional biomass pellet making machine manufacturer and supplier to cooperate with. GEMCO is a professional biomass pellet making machine manufacturer and supplier to cooperate with. Welcome your inquiry and visit!

Video of Straw Pellet Making Machine in Straw Pellet Production Line

Here is the video sent from our customers, showing the working condition of the straw pellet machine plant. If you have idea of starting straw pellet production, don’t hesitate to contact us!

About Making Straw into Fuel Pellet

Straw is actually seen as a kind of crop waste in most situations. There will be plenty of crops straws such as corn straw, rice straw, wheat straw and cotton straw. These straws are annoying for farmers. It will be a great pleasure for them to get rid of these wastes. Some farmers choose to burn the straw directly while some choose to make the best use of them.

The value of straw pellets has not yet received serious attention. There are still a large amount of crop straws being ignored and burned directly, which is not only bad for our health, but also bad for the environment. Starting straw pellet production line is really a promising project in large agricultural countries with rich straw resources such as China, Thailand, Russia, New Zealand and other agricultural countries.