In modern aquaculture, the quality of feed directly impacts farming efficiency and fish health. The heron fish feed machine, specially designed for heron fish and similar aquatic species, has become a crucial tool for many fish feed manufacturing plants to enhance their product competitiveness. Understanding the processing precautions of the heron fish feed machine can effectively prevent malfunctions in the fish feed production line, reduce maintenance costs for fish feed plants, and simultaneously improve the market recognition of the final product.

Setup Your Own Fish Feed Making Plant Business

Setup Your Own Fish Feed Making Plant Business

Three Key Parameters for Heron Fish Feed Pellet Design

In custom production at aqua feed mills, understanding the target species’ feeding and digestion habits is the first critical variable for feed effectiveness. As a typical aquatic fish, the feeding behavior and digestive traits of heron fish dictate the professional standards for fish feed pellet design.

Feeding Behavior and Pellet Density

-

Heron fish are mostly bottom or mid-water feeders, requiring fish feed pellets with appropriate density to ensure sinking or suspension.

-

The pellet density generally needs to be controlled between 1.1 to 1.3 g/cm³, ensuring that the fish can easily consume the feed instead of it sinking too fast or floating on the surface.

Digestive Characteristics and Pellet Swelling Rate Requirements

-

Heron fish have intestinal lengths 30-40% longer than common commercial fish, meaning their digestive systems require strict matching of pellet swelling speed.

-

The hardness and water swelling rate of fish feed pellets must be balanced to avoid rapid decomposition causing nutrient loss or excessive hardness leading to digestion difficulties. The ideal pellet swelling rate target is controlled between 10–15%, ensuring pellets do not disintegrate immediately after absorbing water.

Group Feeding Behavior Impact on Pellet Diffusibility and Water Stability

-

Heron fish exhibit synchronized group feeding; if fish feed pellets dissolve or scatter too quickly in water, it will reduce overall feeding efficiency and feeding control.

-

Pellet stability time in water is recommended to be controlled between 30–60 minutes, facilitating concentrated feeding without polluting the water.

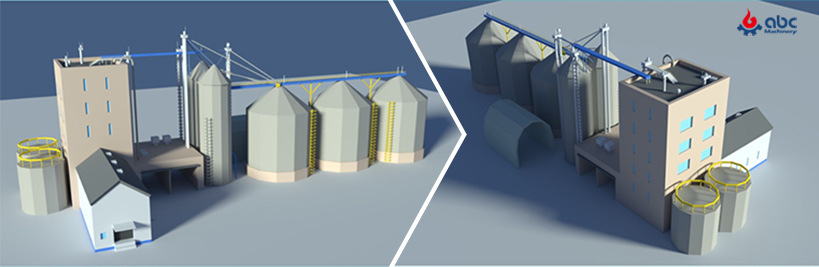

3d Drawings of Profitable Fish Pellet Plant

3d Drawings of Profitable Fish Pellet Plant

These biological behavior details provide precise references for the heron fish feed machine’s processing technology choices. By adjusting fish feed pellet buoyancy, hardness, and water absorption, fish feed machinery can customize pellets that match the heron fish’s ecological habits, helping farmers improve feed conversion rates and fish health. If you wish to receive local demonstration materials, inquire about fish feed extruder machine prices, or consult experts, feel free to contact us for free complete data and technical explanation services!

How to Precisely Select Heron Fish Feed Equipment?

Meeting the high standards of nutrition balance, pellet density, and water stability required for heron fish farming, fish feed machinery selection must comprehensively consider five dimensions: capacity matching, raw material adaptability, pellet control precision, automation level of the fish feed production line, and energy-saving environmental protection of the feed pellet processing machine.

Capacity Matching to Meet Various Fish Feed Plant Needs

-

Ensuring the actual operating capacity of the fish pellet manufacturing machine aligns precisely with the planned production scale of the fish feed production plant to avoid resource waste or capacity bottlenecks.

-

The heron fish feed machine models from ABC Machinery feature a highly modular design. The entire aqua feed mill production line supports interconnection between fish feed processing machines, enabling raw material switching within 15 minutes, greatly enhancing flexibility for small-batch, multi-variety production.

Raw Material Adaptability and Stable Processing Capability

-

The fish feed pelleting machine supports pellet sizes adjustable from 1.5mm to 6mm, meeting the precise feeding needs of heron fish at different growth stages, suitable for both the heron fish feed machine and the fish feed pellet machine.

-

ABC Machinery equips variable frequency speed regulation and automatic PID temperature control systems, precisely matching various fish feed making formula, with a forming rate ≥96%, ensuring high efficiency and stability of the fish feed production line.

Pellet Forming Precision and Stage Adaptability

-

High-quality feed not only needs to be uniformly formed, but also needs to have ideal hardness and stability in water.

-

ABC Machinery's fish feed pellet production equipment is equipped with an automatic die lubrication system and a pneumatic cutting unit. The measured feeding rate is increased by 10%-15%, effectively reducing feed waste and water pollution.

Automation and Intelligence to Improve Production Efficiency and Stability

-

The heron fish feed machine production line boasts automation execution rate ≥95%, with intelligent modules precisely controlling key steps, reducing manual intervention by over 60%, significantly enhancing consistency and capacity efficiency of the fish feed processing line.

-

ABC Machinery’s full line integrates Siemens PLC and touch-screen systems, real-time monitoring temperature, pressure, steam volume, and feeding speed, ensuring the fish feed machine operates stably 24/7, with fault response time shortened to within 2 hours.

Reducing Costs and Meeting Regulations

-

The equipment features high energy efficiency, lowering unit energy consumption (kWh/ton), reducing operational costs and carbon emissions, conforming to green manufacturing standards, suitable for the heron fish feed machine and various fish feed production line setups.

-

ABC Machinery provides hot air circulation and steam waste heat recovery systems, achieving a comprehensive thermal utilization rate of 85%, effectively reducing steam loss, meeting modern fish feed manufacturing machine energy-saving requirements.

-

The production line is equipped with high-efficiency dust collectors and soundproof enclosed systems, achieving dust emissions <20 mg/m³ and noise control ≤78 dB, ensuring a clean working environment compliant with animal feed machinery manufacturers’ environmental standards and protecting operator health.

Complete Fish Feed Pellet Production Line for Sale

Complete Fish Feed Pellet Production Line for Sale

Why Choose Heron Fish Feed Machine of ABC Machinery?

As a leading animal feed machine manufacturers company, ABC Machinery focuses not only on improving fish feed equipment performance but also on creating highly intelligent and sustainable fish feed production line solutions. ABC’s heron fish feed machine and related fish feed pellet machines are widely used in fish feed production plants and fish feed pellet production line setups, helping to improve fish feed processing efficiency and product quality:

-

AI predictive maintenance system, with failure rate below 1.2%, ensuring 365-day stable operation of fish feed equipment.

-

Intelligent maintenance platform supports remote diagnostics and operational log analysis, enabling 80% of issues to be resolved remotely, significantly reducing fish feed plant maintenance costs.

-

All parts in contact with raw materials comply with FDA and EU certifications, meeting global aquaculture feed export enterprises’ compliance requirements.

-

Provides 100% customized fish feed production line solutions, maximizing factory space utilization and optimizing capacity.

-

Raw material purification rate up to 99.5%, effectively preventing clogging, improving fish feed equipment stability by over 30%.

Successful Animal Feed Pellet Plant for Sale

Successful Animal Feed Pellet Plant for Sale

In the fiercely competitive modern aquaculture industry, ABC Machinery’s fish feed equipment and heron fish feed machine are specially designed for heron fish and related species, ensuring the quality of fish feed pellets and production line efficiency. Choosing ABC Machinery means not only advanced fish feed processing equipment but also enjoying full lifecycle services from design and configuration to installation and after-sales support. Contact us today to get tailored fish feed extruder machine prices and technical support!