In recent years, the demand for biomass pellets has grown rapidly. More and more households and small farms are turning to homemade biomass fuels to reduce energy costs and support environmental sustainability. A homemade pellet mill has become a popular solution for individuals, small-scale farmers, and families seeking energy independence. Many users interested in how to make wood pellets at home are looking for compact, efficient machines that can convert sawdust, straw, and other renewable resources into usable pellets.

Small Home Pellet Mill for Sale

Why Choose a Homemade Pellet Mill?

As energy prices rise and environmental awareness increases, owning a homemade pellet machine has become an economical and eco-friendly choice. Whether you’re processing wood waste, agricultural residues, or making animal feed, a small homeuse pellet machine can help you cut costs and reduce waste.

Unlike large industrial pellet machines, homemade wood pellet machines are compact, easy to operate, and cost-effective. They allow users to make homemade wood pellets or animal feed without relying on commercial suppliers.

Applications of Homemade Pellet Machines

- Fuel Pellets (Wood Pellets): Homemade wood pellet machine simplifies the fuel pellet production process. Clean-burning and energy-efficient, wood pellets are ideal for heating stoves, fireplaces, and biomass boilers.

- Animal Feed Pellets: You can easily create custom feed formulas using a homemade pelletizing machine. It’s an efficient way to lower feed costs while improving nutrient utilization.

- Organic Fertilizer Pellets: Using waste like straw, husks, or manure, a homemade pellet maker helps you turn organic waste into high-value fertilizer, supporting sustainable agriculture practices.

How to Buy a Home Pellet Mill for Your Needs?

Choosing the right homemade pelletizing machine for home use requires careful consideration of power type, die size, and production capacity to ensure it meets your specific production needs.

Power Type Selection of Homemade Pellet Mills

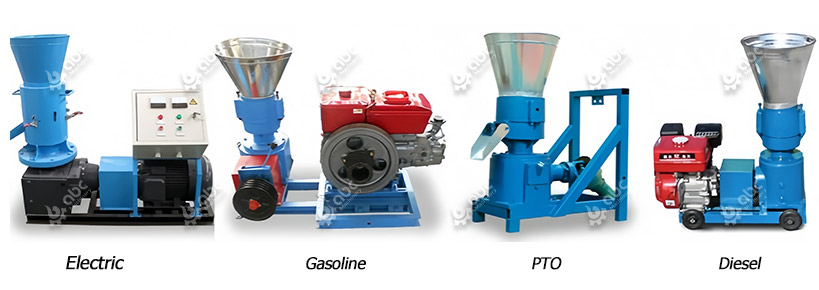

Different power types of pellet mills for home use suit various environments and production demands. You can select the appropriate machine based on your circumstances:

Small Homemade Pellet Mill with Different Power Sources

- Electric pellet mill: Ideal for indoor use with stable electricity supply.

- Diesel pellet mill: Suitable for outdoor use or areas without power.

- Gasoline pellet mill: Portable design, perfect for small farms.

- PTO pellet mill: Tractor-driven, designed for agricultural use.

Machine Quality & Durability of Homemade Pellet Machines

Most homemade pellet mills are equipped with alloy steel rollers and dies to ensure long service life. The sealed bearing design prevents dust ingress and reduces wear. High-quality homemade pellet making machines typically comply with CE certification standards for safety and reliability.

Start Your Pellet Production with ABC Machinery

Factory Price Small Wood Pellet Production Machines for Sale

Why Choose Our Homemade Pellet Machines?

- Over 25 Years of Industry Experience, Proven by Global Users

Our engineering team has integrated over two decades of technical expertise and data from thousands of production lines into the design of every small pellet machine. Our Wood pellet press machines have been successfully installed and are running smoothly in over 60 countries and regions across North America, the EU, Southeast Asia, and Africa—proving their durability and dependability in real-world applications.

- Certified by CE & ISO Standards – Double Guarantee for Safety and Quality

Key components of our small pellet machines are made with alloy steel and treated with advanced heat processing. The entire machine complies strictly with the EU Machinery Directive 2006/42/EC and ISO 9001:2015 quality standards. our equipment is built to meet international safety benchmarks. Multi-layer overload protection, electric interlocks, and low-noise design ensure a safe and efficient working environment—ideal for export or local compliance inspections.

- One-Stop Technical Support: Selection – Installation – Training – After-Sales

Our senior process engineers offer comprehensive front-end consulting, including raw material analysis, equipment selection, and plant layout. After delivery, our technical team will be dispatched for on-site installation and training, free of charge. We keep more than 300 types of spare parts in stock, with commonly used wear parts available for shipment within 48 hours to minimize downtime.

- Highly Customized Solutions to Match Your Unique Process

Whether you’re producing biomass fuel, animal feed, or organic fertilizer, we offer flexible configurations based on your raw materials, production goals, and budget. We design equipment that fits your process—so you don't have to adapt your process to fit the machine.

Tell us your raw materials and daily capacity goals now to get a personalized quote, 3D plant layout, and feasibility profit analysis—making your investment more controlled and returns faster!

How to Use Our Homemade Pellet Mill to Process Pellets?

Mastering the correct operation of a homemade pellet maker can significantly improve pellet forming rate and equipment life before producing biomass pellets, feed pellets, or organic fertilizer pellets. Here are some key steps:

- Prepare raw materials with moisture content controlled between

The moisture level greatly affects pellet quality; too wet or too dry materials lower the pressing efficiency and may cause clogging or loose pellets.

- Use stable and uniform feeding methods

Uneven feeding leads to unstable machine operation, reduces pellet formation rate, increases die wear, and impacts overall efficiency.

- Adjust roller gap and pressure parameters

Different raw materials require different roller and die pressure. Properly adjusting the gap and pressure ensures high pellet density, stable formation, and uniform output.

- Cooling and Storage

Fresh pellets exit the machine at high temperatures and need natural cooling to prevent deformation or mold during packaging and storage. Optionally, use a pellet cooler to enhance efficiency.

If you want to make wood pellets at home or use a homemade wood pellet mill, our machines provide the perfect solution to make your own wood pellets at home.

Want to get the latest prices? Contact us now for free consultation and pricing information! Start your pellet production journey today with reliable and customized equipment from ABC Machinery.