Chicken feed processing is a key link in the farming industry, and its success is directly related to poultry farming efficiency and product quality. In this complex and precise field, every step of chicken feed making line is crucial. This article will delve into the characteristics and considerations of chicken feed processing to provide a full range of practical guidance for farmers to ensure their excellence in this critical aspect.

Key Characteristics of Chicken Feed Production

The characteristics of chicken feed pellet production provide flexible and scientific options for feed processing. The nutritional value of feeds is effectively enhanced through rational use of chicken pellet feed, careful management of fats and oils, scientific use of enzymes, and precise handling of trace perishable ingredients. These strategies not only help optimize chicken feed formulation and improve the production efficiency of the farming industry, but also lay a solid nutritional foundation for the health and growth of chickens.

Mash Feed & Crumble Feed & Pellet Feed & Mixed Feed Pellets

- Rational Application of Feed Pellets

Whether making chicken feed for layers or making chicken feed for broilers, chicken food more choose pellet form. Because chicken feed pellets palatable, reduce grading, avoid picky eating. The diameter of the granular material is generally 3~5mm. But broiler chicks should use crushed material, its diameter is generally 2mm.

When considering buying an animal feed pellet mill and starting your chicken feed production business plan, it is a best practice to clearly state to the animal feed machine supplier the specific type of animal feed you plan to make. By clearly stating your production needs, the animal feed pellet machine manufacturer will be able to equip you with dies that have holes of the appropriate diameter size. If you need it, you can contact us directly.

- Addition and Management of Fats

Adding the right amount of fats and oils can regulate the energy concentration of the ration for chickens. It is recommended to mix fats and oils, but the amount used should not exceed 5%. To ensure the quality and stability of fats and oils, the feed should not be stored for too long, and appropriate number of antioxidants should be added.

- Optimal Utilization of Enzyme Agents

Reasonable use of enzymes to reduce chicken feed costs. Adding non-starch polysaccharide enzyme or composite enzyme in feed has become the main technical way to improve the energy of broiler feed and reduce the amount of fat added. The effect of enzyme preparation is better in the early stage of broiler chickens, especially when added to wheat diet, the effect is more prominent.

- Handling of Sensitive Micro-ingredients

Adopting the process of adding after pelletizing to deal with trace perishable ingredients. Additives that are contaminated or easily damaged in the making pellet process, such as drugs, vitamins, enzymes, and biotin, can be added after pelleting.

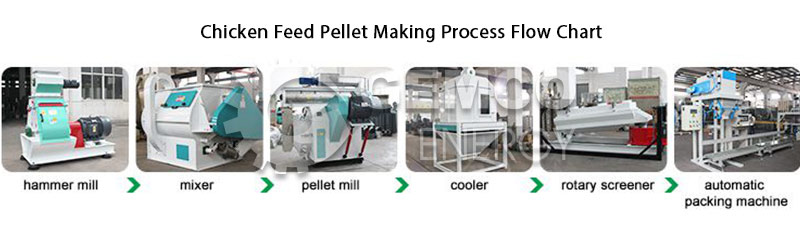

Crucial Points for Making Chicken Feed Pellets in Production Line

There are many considerations to focus on during the production of chicken feed pellets. From the matching of raw materials to pellet production to packaging and storage. Together, these considerations build an efficient, high quality chicken feed making process.

Chicken Feed Making Process Flow Chart

Combination and Proportioning of Chicken Feed Pellet Ingredients

Reasonable matching of feed ingredients can make the nutrients more comprehensive, and the biological value of the feed can be improved through complementary effects. At the same time, it is also easy to formulate feed rations that meet feeding standards. However, too much raw material increases the storage space, increases the energy consumption of crushing, therefore, chicken feed mill plants require comprehensive consideration of costs and benefits.

Adjustment and Residue Cleaning of Chicken Feed Formulas

Stabilize the types and ratios of raw materials, and pay attention to cleaning up residues when substantially adjusting the formula to prevent cross-contamination. Regularly clean equipment and containers to ensure the stability of chicken feed formulation.

Grinding and Moisture Control

Pay attention to the crushing particle size. Crushing is generally required to pass through a sieve of less than 1mm. Control the appropriate moisture. The addition of water can reduce the cost of making feed pellets, provide feed conversion rate and animal growth rate. It should be noted that the general water content of pelleted feed does not exceed 16%. However, Which Chicken Feed Pellet Making Machine Is Suitable for Processing High Water Content? Let us reveal the answer next.

Flat Die Chicken Feed Pellet Mill & Ring Die Chicken Feed Pellet Mill

Choosing a Pellet Machine for Chicken Feed Based on Raw Material Characteristics

Flat die feed pellet mill and ring die feed pellet mill are both used for processing pellet feed, etc., and they have some different characteristics when dealing with different raw materials.

- Flat Die Feed Pellet Mill

Flat die feed pellet machine mainly presses the raw material into pellets by means of a flat die. Because of its relatively simple structure, easy operation and strong adaptability to raw materials, flat die feed pellet machine is suitable for small scale chicken feed production. In addition, flat die pellet mills are also frequently used as homemade feed pellet mills and are ideal small chicken feed pellet machines to make chicken feed at home.

- Ring Die Feed Pellet Mill

Ring die feed pellet machine uses ring-shaped molds in which the raw material is rolled inside the mold, resulting in a higher compression ratio. Therefore, it is suitable for manufacturing raw material with high water content. Ring die pellet mill is more complex than flat die pellet mill, but is usually superior in pellet density and hardness. Ring die pellet mill is popular as a large chicken feed making machine among chicken feed plants.

Contact us for more information on chicken feed making machines.

Starch Gelatinization and Amino Acids

Pay attention to the starch pasting degree. Allowing the starch in the raw material to be pasted as much as possible is an important method of producing high quality pellet feeds, but too much pasting can reduce nutrient utilization.

Pay attention to the effect of processing on amino acids. The chicken feed manufacturing process causes amino acid losses; therefore, pellet diets should increase the lysine and methionine concentration of the diet.

Feed Fine Powder and Mold Prevention

When the modulation time and temperature are insufficient, the pellet stability is poor and the increase of fines affects the quality. Therefore, chicken feed plants should choose the right chicken feed grinder machine and optimize fines process.

Use suitable mold inhibitors, preservatives, or antioxidants to prevent mold. Propionic acid and its salts are commonly used as mold inhibitors in broiler feed.

Storage and Preservation of Chicken Feed

Complementary feeds should not be stored for a long time. Without adding antioxidants and mold inhibitors, the storage time is not more than 7~10 days, and it is better to mix it as you use it. Besides, when chicken feed pellet mills make chicken feed pellets, packing and sealing the pellets is important to maintain the quality of the pellets and prevent moisture and pests.

You are welcome to ask us any questions and needs you may have about the manufacturing process of making chicken feed and the complete chicken feed production line. We will provide free and professional answers.