We can Guide You on Building Chicken Feed Pellet Mill Plant Step by Step

Business Scope

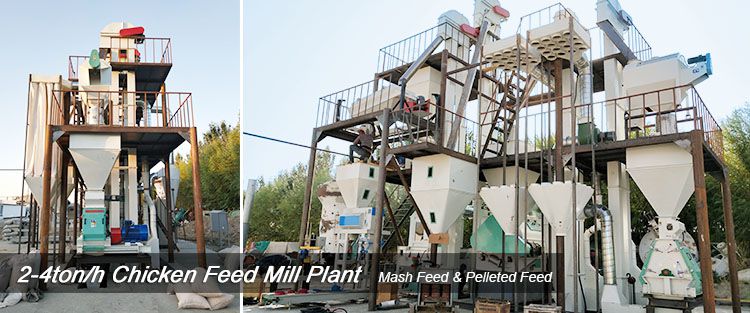

We offer customized project plan of establishing chicken feed pellet mill plant, based on your specific capacity needs, cost budget, raw materials and factory situation.

- Production Output: 1-150 tons/hour

- Application: Make mash feed and feed pellets (2-10mm) for different livestock & poultry animals (cattle, cow, goat, chicken, pig, fish, etc)

If you are planning to start your own chicken feed manufacturing business and need complete set of poultry feed pellet mill or mash feed processing equipment, ABC Machinery is surely your first choice! We offer tailor-made feed production business plan to ensure the success of your company. (Project Report: 1ton/h commercial feed mill equipment >>)

Setup A Complete Chicken Feed Pellet Mill Plant

The main equipment for establishing a complete chicken feed pellet plant includes hammer mill (crushing machine), feed mixing machine, animal feed pellet machine, cooling equipment, feed packaging machine and other auxiliary equipment. Our feed processing technical team can help you on customized poultry feed mill project plan and cost details of any capacity. (Read more about industrial poultry feed making process >>)

Chicken Feed Crushing Process

Crushing is the process of making the raw fodder material into smaller particles by mechanical external forces (such as impact, shearing, grinding, etc). For grain, crushing is to smash the shell of the grain and expose the internal nutrients. At the same time, the surface area of the seeds increases sharply, so that the material has more opportunities to contact the digestive juice in the poultry's digestive tract and improve the digestion of feed, reduce poultry excretion, nutrient loss and environmental impact. A study by Kansas State University showed that feeding broiler chicken with crushed corn increases the meat ratio by 1.3% for each 0.1 mm decrease in average particle size.

Feed Batching Process

- On the premise of ensuring the accuracy of the electronic scale ingredients, weigh the large materials first, and then the small materials;

- When batching, the raw materials with small bulk density should be poured first, and then the bulky raw materials should be poured to prevent the raw materials from splashing out of the warehouse and causing unnecessary injuries to workers;

- The material distributor located on the top of the batching warehouse uses a rotary distributor for batching, which improves the accuracy of batching and quality of feed processing, and reduces feed loss.

Feed Mixing Process

Mixing is to feed the prepared materials into a mixer with good processing performance to fully mix them, so that the various components of the materials are evenly distributed, which prevents the nutritional imbalance and the inconsistent bulk density, and get better feeding effects.

Conditioning and Pelletizing Process

Conditioning is to pass the feed through a conditioner with high temperature and high pressure steam to promote the denaturation of protein contained in the feed, increase the degree of starch gelatinization, promote the conversion of starch into soluble carbohydrates, and change the physical and chemical properties of the feed to make it more conducive to animal breeding. After conditioning, the feed mixture will fed into feed pellet mill to be extruded into uniform pellets of desired size.

Particle Size of Final Feed Pellets

Bigger pellets can increase the feeding speed, but bad for the digestion. Smaller pellets can less efficiency of foraging, but good for animal digestion. Suitable feed size can significantly improve the nutritional value of the feed, reduce the production cost, but also can improve the animal feed intake and nutrient digestibility, reduce the amount of animal feces. (Read more about chicken feed pellet machine >>)Feed Pellets Cooling Process

The cooling effect is related to ventilation, time, temperature and speed. If the time is too short, the cooling will be insufficient and will not achieve the desired effect. If the temperature is too high, the cooling rate will be slowed down and production efficiency will be reduced.

The quality of feed pellets is directly related to the reputation and benefits of your chicken feed pellet mill plant. It is one of the important indicators for the progress and development of feed science and technology, and it is also the main aspect that farmers care about feed.