With the global aquaculture industry’s output exceeding $300 billion (FAO, 2024), tilapia (Tilapia), an important species with annual production surpassing 15 million tons (Ministry of Agriculture and Rural Affairs, 2023), has driven significant technological innovation and commercialization in tilapia fish feed pellets. This sector has become a key link in the global fish feed production and export supply chains. This article highlights tilapia’s farming value while integrating insights on the design and layout of fish feed production plants and smart animal feed pellet production line to boost farming efficiency and processing productivity.

Buy Tilapia Fish Pellets Equipment to Start Your Business

Buy Tilapia Fish Pellets Equipment to Start Your Business

The Farming Value of Tilapia

High-quality tilapia fish feed pellets not only improve farming performance but also ensure fish health and market competitiveness. Understanding and precisely grasping tilapia’s farming value is the first step for a fish feed pellet production plant to achieve scalable, standardized aquaculture and ensure sustained profitability.

-

Cost-effectiveness: Using pellet feed for fish in tilapia farming systems results in a high feed conversion ratio (FCR around 1.5–1.8). Numerous studies indicate that plant proteins like soybean meal and corn gluten can replace over 40% of fishmeal, reducing feed costs by 15% to 25% in fish feed making factories.

-

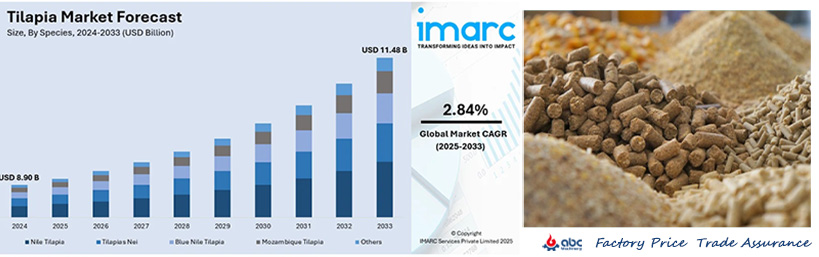

Stable market demand: Global production exceeded 6.9 million tons in 2023 (FAO), with annual export growth averaging 6.8%, providing broad market opportunities for fish feed manufacturing plants.

-

Adaptable farming methods: Suitable for large-scale pond, cage, cement tank, and recirculating aquaculture systems, supporting extensive farming, eco-agriculture, and integrated aquaculture models.

-

Strong environmental tolerance: Temperature range adaptability from 20°C to 35°C, optimal growth at 26–30°C, with good resistance to low oxygen and poor water quality, surviving in low water or semi-polluted conditions.

-

High reproductive capability: Early sexual maturity, with broodstock spawning more than once per month and fry hatch rates exceeding 85%.

Learn the Farming Value of Tilapia Fish Feed Pellets

Learn the Farming Value of Tilapia Fish Feed Pellets

Since tilapia farming environments and scales vary by region, a one-size-fits-all fish feed production line cannot meet all needs. If you are troubled by low feed conversion, high costs, or mismatched fish feed machinery, don’t hesitate to contact us! We offer free customized fish feed processing line and plant design solutions to help you maximize farming profitability.

Design and Layout of Tilapia Fish Feed Pellets Plants

With the rapid growth of global aquaculture, building a modern fish feed mill plant is key to enhancing enterprise competitiveness. Scientific factory design and reasonable fish feed production line layouts not only affect production efficiency but also directly influence energy consumption, production costs, and product consistency in fish feed pellet production plants.

Design Philosophy: From “Production Function” to “Operational Logic”

-

Efficient fish feed production plants design should prioritize material flow, avoiding backflows, cross-transport, or redundant handling. Reasonable layouts improve overall production efficiency by 12%–18% and reduce energy consumption by about 10%.

-

ABC Machinery employs multiple layout models such as “U-shape,” “L-shape,” and “linear” designs in fish feed machinery line planning, customizing the “shortest flow path” according to factory dimensions, effectively saving 10%–15% on energy and transport costs.

Core Workshop Layout: Compactness and Future Expandability

Grinding + Mixing Area: Located near raw material entry to reduce transportation energy

-

Coarse and fine grinders should be positioned close to raw material storage to minimize vertical conveying heights. Mixing bins reserve 3–5 formula interfaces for easy product switching.

-

ABC Machinery offers a compact three-in-one design integrating elevator + pre-cleaner + grinder lines, saving more than 20% floor space, paired with dual-spiral mixers achieving a uniformity coefficient (CV) ≤ 5%, exceeding industry averages of 6%–8%.

Conditioning + Extrusion Area: Core energy consumption zone, ventilation and insulation prioritized

-

In the fish feed production line, conditioning and extrusion consume the highest energy, accounting for 35%–40% of total. Scientific feed mill plant layout such as wall-mounted fish feed manufacturing machines placement can reduce heat loss by 12%.

-

ABC Machinery’s fish feed machinery system uses dual cooling (air + water), effectively controlling moisture in fish feed pellets below 10%, reducing mold risk.

Tilapia Fish Feed Pellets Making Line for Sale

Tilapia Fish Feed Pellets Making Line for Sale

Upgrade Your Tilapia Feed Plant with ABC Machinery

In the competitive tilapia feed market, traditional manual operations and experience-driven processes no longer meet high standards for quality, efficiency, and safety. According to the International Feed Industry Federation (IFIF), over 70% of global aquaculture feed companies are pursuing digital transformation. ABC Machinery understands that only intelligent, digital production systems can truly reduce costs, stabilize quality, and accelerate responsiveness.

Our key advantages include but are not limited to:

-

Intelligent batching systems dynamically adjust feed ratios per fish feed pellet size formula with an error margin under ±0.1%, verified to reduce raw material waste by 3%–5%.

-

Full traceability: 100% batch records supporting export certifications and customs inspections.

-

24/7 cloud platform inspection, reducing manual operation costs by 30%, and fault response times by 40%.

-

Flexible multi-formula seamless switching: storing and quickly switching among multiple tilapia feed formulas to meet different growth stages and market demands, improving response speed and customer satisfaction.

Successful Tilapia Feed Pellets Plant for Sale

Successful Tilapia Feed Pellets Plant for Sale

Choosing ABC Machinery means partnering with cutting-edge industry technology. We not only supply fish feed pelleting machines but also offer smart production solutions and expert technical support to help your tilapia feed mill plant undergo digital transformation and lead the competitive market. Contact us now for a free customized intelligent production solution and start your feed mill’s smart upgrade journey.