Most Profitable Business Choice: Making Wood Wastes into Fuel Pellets

Wood Pellet Making Business Plan Process Design Low Cost

There are always people looking for new sources of fuel, and biomass wood pellets have been growing in popularity as a new energy source for many industrial and commercial uses. Production of biomass wood pellets has increased by 10 percent over the past few years and is expected to continue to grow as more fuel systems are converted to use them. (Related article: wood pellet making machine price>>)

Rising prices for fossil fuels such as fuel oil and natural gas are leading to increased interest in wood pellet heating. Concern over global climate change is also stimulating interest in wood pellets and other “carbon-neutral” energy sources. In many American and European countries wood pellets are used in co-generation, where steam is produced to turn turbines to generate electricity and to heat homes and offices in the winter. If you have any questions about wood pellet making, you can contact us for more infomation!

Wood Pelleting Technology for Wood Pellets Making Business Plan

Wood Pelleting Technolgy Principle

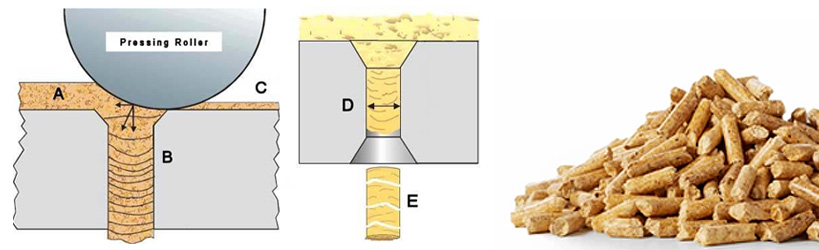

How Wood Pellets Are Formed?

Wood chips, straw and other materials contain a certain amount of cellulose and lignin. Lignin is non-crystalline at room temperature, mainly distributed insoluble in any solvent, no melting point, but has a softening point. When the temperature and pressure reach a certain point, the softening bond of lignin increases, its cellulose molecular group is dislocated, deformed and extended, and the adjacent molecules inside will be reassembled and pressed into shape, therefore, there is no need to add any additive or binder during the processing of wood particles. (Read more: wood pellets calorific value>>)

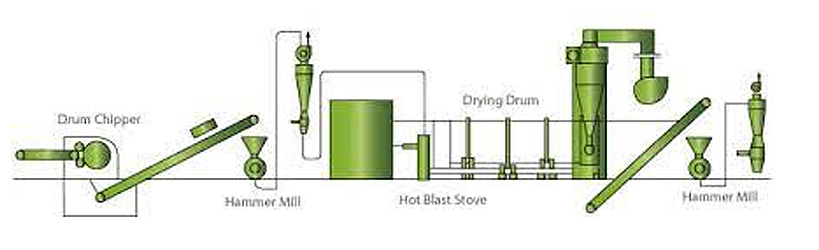

Complete Wood Pellets Production Process Design

Wood Pellet Making Process Deisgn at Low Cost

- Raw Materials Pretreatment

The production of wood pellets begins with the generation of the raw material. In most cases this raw material is a byproduct of some other wood processing operation, like clean (no bark or dirt), dry sawdust and small scrap blocks etc. and there are also producer using wood logs to make wood pellets.

Crushing: Wood chips above 50 mm in size must be crushed in chippers and hammer mills before entering the drying process

Drying: wood waste materials with high moisture content should be dried until the moisture content within 14%-16% by a dryer

Mixing: this step is for the multiple wood residues, to make the various materials together.

- Formation of the Pellets

Pellets are extruded using special dies. High pressure (45,000 PSI) and temperatures (200 F) are generated in this process, which softens lignin in the wood and binds the material in the pellet together. No additional adhesives are required, although sometimes small amounts of lubricants may be added to improve processing.

- Wood Pellets Bagging and Storage

Once the pellets are formed and cooled, they are packaged in bags or stored in bulk. Most residential pellet users buy pellets by the ton, which consists of 50 40-pound bags packed on a pallet. The pellets may also be placed in small silos outside of the user’s home by a delivery truck. Pellets can be stored indefinitely but they must be kept dry to prevent deterioration. The formed wood pellets are cut into the same-length cylinders and discharged.

Note: the production process is deisgned based on the requirements of the customers, we offer the customization solution. Welcome to contact us for the latest price list.

Key Equipment to Setup Wood Pellet Production Business

Wood pellet mill is a new biomass energy generating equipment, a pelletizing equipment for wood chip pellet production; it takes eucalyptus wood, birch wood, poplar wood, fruit wood, bamboo chips and crop straw as raw materials, and makes finished wood chip pellets through the process of crushing, drying, screening, pelletizing, cooling and packing. Its finished products are used in biomass power generation, boilers, fireplaces, household equipment etc..

-

Flat Die Wood Pellet Mill for Startups Business

Small wood pellet machine is very suitable for making wood pellets in farms, backyards, small workshops and other places without convenient electricity. According to the working principle, small flat die wood pellet mill is divided into two large types: die-rotary type (D-type) and ring rotary type (R-type).

Factory Price Small Flat Die Wood Pellet Making Machine

(Left: D-type wood pellet mill, Right: R-type wood pellet making mill)

D-type small wood pellet mill has equipped with different driving engines including electric, gasoline, diesel and PTO (driven by a tractor), processing various of wood residues.

R-type mini wood pellet machine is newly designed and developed for pelleting the hard wood wastes into pellets, like oak, mahogany & birch, red oak, hard maple, alder, beech, boxwood etc.

-

Ring Die Wood Pellet Machine for Large Business Plan

Large ring die wood pellet machine consists of two types based on the feeding styles, they are horizontal type and vertical type.

Low Cost Ring Die Wood Pellet Making Machines for Sale

(Left: Horizontal ring die wood pellet mill, Right: vertical ringd die wood pellet machine)

Horizontal type ring die wood pellet machine is the common large scale pellet machine, widely used for large scale wood pellets making line and pellet fuel manufacturing factories.

Vertical type uses vertical feeding style, is newly designed and developed for processing light-weight raw materials in the wood pellets making plant.

Keep Your Wood Pellets Making Business Growing with Our Global Service Network

The growing utilization of wood pellets in power generation is one of the key factors driving the wood pellet market. In addition, the following factors are also playing a contributing role. (Related article: biomass wood pellet cost analysis>>)

- Increasing awareness among individuals regarding the benefits of using renewable energy sources and the high combustion of wood pellets is driving the growth of the market.

- Rising oil prices and increasing use of wood pellets to heat federal and municipal buildings, office buildings, and educational facilities are providing lucrative growth opportunities for end users.

- More and more governments are offering incentives and subsidies to encourage the adoption of renewable energy for power generation, which in turn is positively impacting the global sales of wood pellets.

- Major market players are focusing on consolidation and collaboration to expand their customer base. These players are also working on sourcing waste wood and sawdust to increase production, which is expected to increase their overall sales and profitability.

Different Scale Wood Pellet Making Plant Cost Reference ($)

- 2TPH: 70,000-15,0000 USD

- 5TPH: 150,000-300,000 USD

- 10TPH: 350,000-1000,000 USD

Sucessful Wood Pellets Making Plant Setup around the World

|

Project Location |

Project Name |

|

Australia |

|

|

Italy |

|

|

Chile |

|

|

Indonesia |

ABC Machinery is a professional manufacturer and supplier of wood pellets and equipment, committed to providing customers worldwide with good value for money pellet manufacturing equipment, feel free to ask us for advice.

FAQ about Wood Pellets Produced from Wood Pellet Making Line

- What Are Wood Pellets?

Wood pellets are cylinders with the same length and diameters, compressed from wood waste and forestry residues by a wood pellet machine.

Suitable raw materials: sawdust, wood shavings, tree branches, tree branches, tree trunks, tree leaves, wood blocks, wood boards, wood chips, offcuts, edges, board edges, waste wood, waste wooden furniture, wooden brackets, bamboo residues etc.

Resources: wood product factory, furniture making factory and forestry industry etc.

- Why Pelletize Wood Waste?

Small volume, high specific gravity, combustion resistance, high heat generation, easy to store and transport

High purity, no other impurities that do not produce heat

Very little ash produced after burning biomass fuel, greatly reducing the ballast site and cost

The ash after burning biomass fuel is a high-quality organic potash fertilizer with high grade, which can be recycled for profit.

- What Can Wood Pellet Be Used?

Civil heating and living energy: high combustion utilization, easy to store, easy to use, safe and sanitary.

Biomass industrial boiler: as the main fuel for industrial boiler, replace coal, heavy oil and natural gas to solve environmental pollution.

Power generation: can be used as fuel for thermal power generation.

It also can be used as the materials for cat litter, horse bedding and cattle bedding etc.