Wood pellet production technology belongs to the category of renewable energy. In recent years wood fuel pelletizing is becoming a hot promising investment project. Referring to the cost of wood pellet production projects, it is affected by a number of factors.

Buying Biomass Pellet Making Machinery For Business

ABC Machinery is one of the best biomass wood pellets manufacturing equipment manufacturers and suppliers with its own equipment processing factory, all the wood pellet machines and complete wood pellet production line are on sale at factory price. There are different prices for different machines, if you want to know more about the price, please contact us.

What Will Cost During the Complete Biomass Pellet Production Plant?

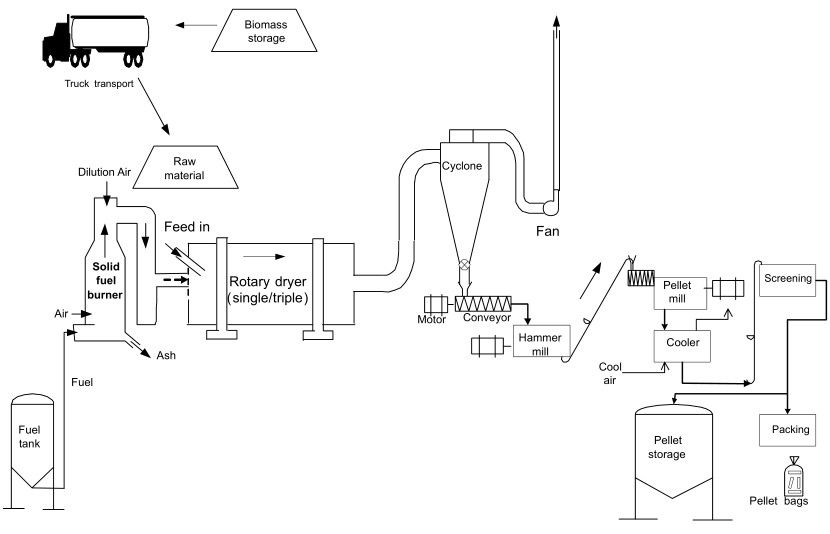

In order to understand the cost of biomass wood pelletization, you should know about where it should cost much during the biomass wood pelletization process. Let's have a look at the layout of a typical biomass pelleting plant.

Schematic layout of a typical biomass pelleting plant

From the layout flow chart above, we can see that building a complete wood pellet plant needs a series of machines, instead of needing a wood pellet mill only. And in this process, the cost of biomass pelletizing is affected by many factories. (Learn more: sawdust pellet machine for sale>>)

Factors of Affecting the Cost Of Biomass Pelletizing

- The local raw material costs (including transportation costs)

- Production energy costs

- Machine wear and maintenance costs;

- Other fixed assets depreciation cost;

- Labor costs

- Business management costs (including tax, sales, transportation, etc.)

These costs vary from place to place. What we can offer is energy consumption cost. Generally, the energy consumption cost is 110-190kWh/t. It might be slightly different depending on different raw materials and productivity. Expanding the production scale can further reduce the cost. (Read more: wood pellet making machine>>)

Small Scale Wood Pellet Making Plant With Low Price

Fctory Price Wood Pelleting Line Project

Next, we would like to show a series of data for your reference.

Pelletizing Industry Data in the UK

| Local raw material costs (including transportation costs) | $24.5~34/t (32.81%~35.50%) |

|---|---|

| Production energy costs | $5.44~17/t (7.88%~16.40%) |

| Machine wear and maintenance costs | $8.16~15.64/t (11.8%~15.09%) |

| Other fixed assets depreciation cost | $1~2/t (1.45%~1.93%) |

| Labor costs | $10.88/t (10.50%~15.76%) |

| Business management costs (including tax, sales, transportation, etc.) | $19.04~23.12/t (22.31%~27.59%) |

| Total cost | $69.02 ~ 103.64 / t. |

Buy a factory price mini flour mill plant from biomass wood pelletization equipment, learn to process grain flour, get FREE guidance to setup mini flour mill plant projects for business in Russia, USA, Chile, Japan, Malaysia, England etc.. Welcome to send messages to us!

What About The Profit Of Processing Biomass Wood Pellets?

When we talk about the cost of making biomass wood pellets, we have to talk about the profits of starting biomass wood pellets production. Here , we analyzed the wood pellets price and profit in the US market. (Related article: biomass pellets price >>)

In the US market, the retail price of small package wood pellets is about $170 / t. The retail price of a large package is about $135/t. In Sweden the delivery price is around $150 / t. For loose-packed wood pellets, the FOB in Amsterdam is about $80 / t. The production cost of biomass pelletization is about $48.78 / t. So there is no doubt that biomass pelletization has great international market competitiveness. Investing in this green energy market is very promising. (Read more: wood pellet business plan>>)

A complete wood pellet line includes equipment of slicing, drying, crushing, pelleting, dedusting, cooling, screening, storage and packaging. The output can be 200 ~ 500 kg/h. Our pellet line can process all kinds of wooden materials, such as forest felling, fuel wood, wood processing residues, furniture production wastes, etc. It can also deal with crops straw, such as corn stalk, rapeseed, cotton stalk, etc. More information about biomass pellets price in your country? Contact us now!

Start to Investing In Biomass Wood Pellet Production Business

Driven by the vigorous development of new energy, biomass energy utilization has gained widespread attention, and the biomass power generation industry is flourishing, showing the bright future prospect. a dn with the obvious progress of products and industries, biomass pellet making equipment has been being used in many aspects of our life. (Read more: wood pellet machine canada >>)

- Civil boilers, fireplaces, industrial boilers: Along with the policy transformation of boilers and other equipment in many provinces and regions, coal burning is prohibited.

- Wood pellets are a good choice. So there is a market where boilers are used, such as chemical, paper, bathing centers, heating units and so on.

- Power generation plant. Biomass power generation has been developing rapidly in recent years, wood pellets are also a clock option, so you can go to the local power plant to see the market.

- Other uses, such as hardware baking paint, grain drying, baking tobacco, smelting financial aluminum, very wide.

The use of wood pellets is very wide, the most common is the boiler, now a relatively large piece of the market. The market has a broad prospect, waiting for your development. When you have plans to start investing in a biomass wood pellet production business, please contact us for more information, we are always for you!

Global Demand Analysis of Biomass Wood Pellets

As a renewable energy source, wood pellets are subsidized and incentivized by many governments, and in recent years, many countries have either initiated or updated their policies and programs related to wood pellet heating applications. (Related article: how to make coco peat pellets>>)

(图片:全球颗粒市场图片 描述:global market of biomass pelletization)

Overall, the global market for heating pellets remains huge. Global demand for heated pellets in Western countries is estimated to reach approximately 26 million tons in 2027, up from an estimated 18.2 million tons in 2020. The global wood pellet market is estimated at USD 10.52 billion in 2020 and is expected to reach USD 15.63 billion by 2026, growing at a CAGR of 7.28% from 2021 to 2026. In 2019, the consumption of wood pellets for heating applications is mainly in Europe, followed by North America and Asia. Europe is expected to dominate the market during the forecast period with the high production of wood pellets in 2020. (Read more: how to make wood pellets >>)

Where Are the Biomass Wood Pellets Widely Used?

Wood pellets for heating applications are used primarily in the residential and commercial sectors for food, cooking and grilling and for heating homes. Since the cost of pellets has long been lower than the cost of other fuels, it has become a more economical option, solving a major problem in the residential and commercial sectors. (Learn more: rice husk pellet machine price>>)

(图片:木屑颗粒在行业内分布图 描述:fields distrubution of biomass wood pellets around the world)

According to the World Bioenergy Association, wood pellets have the potential to replace coal in power generation facilities. In recent years, as technology has evolved, wood pellets have undergone a number of thermal upgrades through various processes such as baking, hydrothermal carbonization and steam blasting. The thermal upgrading allows wood pellets to be used as a fuel with coal characteristics. Asia Pacific, which has the largest number of coal-fired power plants globally, is expected to be a market growth opportunity in the near future.

If you have any questions about processing biomass wood pellets or building a biomass wood pelletization plant, you can feel free to contact us!