In fish farming, making quality feed is crucial. Processing fish feed with fish extruder machines is key to improving feed quality and feeding efficiency. However, this process requires attention to many key details, from raw material selection to proficiency in fish feed processing techniques. In this article, we will discuss fish feed process techniques for making fish feed using a fish feed extruder machine to help investors optimize the production process and improve the nutritional level and growth performance of fish.

Fish Feed Processing Technology of Animal Feed Extruder Machine

Why Opt for Fish Feed Extruders: Advantages in Aquafeed Production

Difference Between Common Fish Feed Pelleting Machine and Fish Feed Extruder Machine

Common Small Animal Feed Pellet Machine

Common fish pelleting machines press raw materials into pellets through mechanical pressure. Fish feed making machine is cheaper, simple to operate and suitable for general fish feed production. It retains the nutrients of the feed but cannot be processed at high temperatures. Therefore, common fish feed pellet machine lacks the characteristics of high temperature sterilization of fish feed extruder machine.

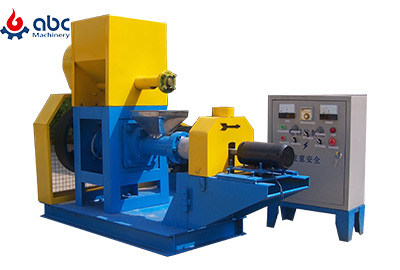

Fish Feed Extruder Machine

Fish feed extruders utilize a high temperature and high pressure environment to process the feed to form low density, more digestible and absorbable expanded pellets. This equipment improves the nutritional value and digestibility of the feed, as well as possessing sterilizing properties. Therefore, the feed pellet extruder machine is suitable for special feed production areas that require high feed quality.

Expanded pellets have significant benefits for all types of fish. They provide a wealth of nutrients and are easy to digest, contributing to the healthy growth of fish. The advantages of expanded pellets will be discussed in detail next.

- Enhancing Feed Palatability and Digestibility: The extrusion process can make the feed pellets easier to be digested and absorbed by the fish, improve the taste and digestibility of the fish feed, and help the fish to better absorb the nutrients. Fish expanding feed pellet can improve the digestibility of 10% to 35%.

- Sterilization and Antinutrient Elimination: Expansion can kill microorganisms in the feed to a certain extent, reduce the anti-nutritional factors in the feed, and improve the hygiene safety and nutritional value of the feed.

- Improving Feed Stability and Longevity: Expanding can improve the stability of feed pellets, reduce the loss during storage and transportation, and prolong the shelf life of fish feed pellets.

- Increasing Flotation Capacity of Fish Feed: Proper expanding can make the feed pellets float in the water, making it easier for fish to approach and ingest the food, especially for breeding fish that are more active at the water surface.

- Ensuring Pellet Uniformity and Controllability: Expanding technology ensures that fish food pellet size is uniform, which facilitates the mixing of feed ingredients and the consistency of the feed, and also makes it easier to ration and control the feed.

If you want to know more advantages of animal feed extruder machines or more applications of extruder machines in the field of feed production, you can directly consult us to get free consultation and fish feed extruder design!

Essential Points in Fish Feed Manufacturing Process with Feed Extruders

If you want to succeed in your fish feed production business plan using a fish feed extruder, there are many things in the fish feed production process that deserve your attention.

Fish Feed Pellets from Fish Feed Plant

- Design of Fish Feed Making Formula

When designing fish feed formulations, it is especially critical to ensure that the starch content is above 20% ~ 40%. Low starch content may affect the water resistance and puffing effect of fish feed pellets, as well as lead to increased dust in the finished fish food product and affect the appearance of the pellets. In addition, fat content is controlled between 2-5%. Especially, plant-based raw materials are easier to puff than animal-based ones. Therefore, plant-based raw materials deserve priority.

- Selection of Templates for Fish Feed Extruder Machine

As the pressure difference between the inside of the animal feed extruder machine and the atmospheric pressure needs to be greater. To ensure better expansion, the opening ratio of the expanded feed template during fish feed making process should normally be less than 40%. In addition, the template design is based on the requirements of the volumetric capacity (weight of feed per unit volume) of the fish feed. This is because too high a porosity can lead to problems such as uneven pellets and difficulty in expansion.

- Control of Moisture in Fish Feed Production Process

During the production of expanded feed, the amount of water added to the conditioner is usually about 25% of the total formulation for a general formulation of expanded fish feed.

- Temperature Control in Fish Feed Production Line Adjustments

In general, during the fish food manufacturing process, the temperature is controlled between 90℃ and 95℃. This is conducive to the full maturation of the starch, so that the degree of maturation of the expanded feed reaches 80% to 95%. If the temperature is too low, it will affect the ripening effect and may lead to poor feeding of the fish food extruder machine.

- Control of Extrusion Chamber Temperature in Fish Feed Extrusion Process

The temperature of the extruding chamber of the fish feed pellet extruder machine of the fish feed processing line is generally controlled at about 120-130℃.

- Control of Dryers in Fish Feed Production Lines

In fish feed production plants, the dryer drying temperature is controlled at about 120℃ and the belt speed is maintained at about 40 minutes. Belt-type continuous dryers are usually used. Belt-type continuous dryer machine has the advantages of high output, small footprint, even drying, easy cleaning, easy operation and energy saving.

If you are looking for feed extruder manufacturers to learn about feed extruder for sale or fish feed mill layout design, don't hesitate to contact us directly. We will offer you the best fish feed extruder machine prices and service. Contact us to get free and professional answers immediately.