In this post, let have view of some tips for operating a poultry feed factory. ABC Machinery - a experienced chicken feed making machine factory, will talk about the preparation before start the poultry feed manufacturing production, matters need attention during the feed making processing and what to do when stop the production.

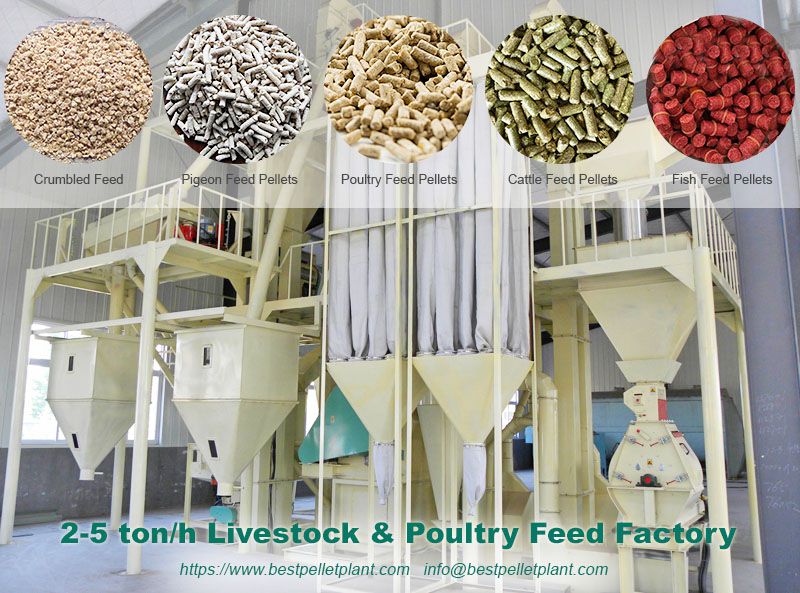

- For starting a 2-3 ton/h feed factory for making mash feed or pellet feed, about $60,000 to $80,000 is needed for purchasing equipment.

- For starting a 5 ton/h feed milling factory (mash feed & pelletized feed), about $130,000 to $150,000 is required for machinery investment.

Recommond Post: Commercial Feed Mill Equipment for 10 ton/h production

Preparing for Running the Poultry Feed Factory

Check the schedules before starting the poultry feed production: Before starting making poultry feed pellets or chicken feed pellets, make sure that all the necessary preparations are done to ensure an effective and steady working process.

Complete the following steps:

- Make sure that the cooler, pipe, and windpipes included in the feed making factory are free from any residues, taking note that the insides of the animal feed pellet machine should be cleaned before the night shift.

- Check the equipment status and see whether the feed pellet machine is working properly.

- Check the grading sieve and replace if necessary.

- Make sure that the clearance of the feed crusher is in good condition to produce high-quality poultry feed products.

- Check the following parts: guiding knife, ring-die, scraper, and the guiding knife’s position.

After completing the steps above, start to run the poultry feed factory and reduce the steam to slow the production rate. When the poutlry feed pellet machine has been running for an hour, it can complete the grinding procedure. Make sure to adjust the gap in between the roller and the annular mode. Doing so will place the ring mode in idle position until the rollers stop turning. After this step, you have completed the preparatory procedure and can proceed on.

Matters to Attention during the Poultry Feed Making Processing

How to start the poultry feed making system and maintaining its optimal performance? Any incorrect procedure and operation in this process will largely affect the quality of the feed production. To prevent machine blockages, it is crucial to use the relevant equipment in sequence according to the correct flow of procedure. (Learn about 20 TPH Poultry Feed Mill Plant Layout >>)

Make sure the regularly do the following:- Check and observe the pellet machine ammeter.

- The system is in a stable condition if the meter is not swaying back and forth.

- Provide ten minutes of our time in cleaning the workspace and areas around the feed pellet making machine.

Recording production parameters and checking the feed production process

When running your poultry feed factory, the following steps must be done and completed every hour to check the feed manufacturing process and record the parameter of the poultry feed production:- Make sure that the produced feed pellets are at the right temperature.

- Take the feed to check its durability.

- Check the ratio of the powder with regards to the finished poultry feed pellets.

- Check the feed crushing roller’s clearance.

- Ensure that the return tube of the centrifugal dust collector and grading sieve is properly blocked.

In doing the steps above, also make sure that all the poultry feed production parameters are recorded systematically including the production time, durability, material temperature, powder ratio, tonnage, production variety, efficiency, and the like. Make sure that attention to the control screen is given while coordinating the pelletizing and packing efficiently to ensure that it is returned to the front and back pockets in time. Keep watch for any problem that may arise to prevent any losses in poultry feed production like having a high amount of powder or the presence of small particles in the fodder material.

Tips for Stopping the Poutlry Feed Production of your Feed Factory

Here are th steps to follow when turning off the poultry feed production or shutting down the feed factory. Before completely shutting down the poultry feed manufacturing equipment, make sure that the low level of the ring die feed pellet machine is seen.

- A way to do this is by opening the feeding door of the machine to see the feeding flow.

- Do the following steps carefully:

- After the fodder material flow has reduced, let it manually discharge.

- Return to the machine with the tube material and wait for a few minutes before placing the remaining material inside the cooler.

- Check all the parts of the equipment including the centrifugal separator, crusher, grading sieve, and cooler to see if there is accumulated feed present.

- Shut down the power supply of the equipment fully.

- Clean the equipment to ensure that there is no residue left on various parts of the machine.

By following these steps and procedures carefully, high-quality poultry feed pellets can be produced. As such, poultry feed factory operators should have a wide knowledge of the feed processing equipment and how to operate it effectively.