The chicken feed industry is a multifaceted development influenced by some factors, of which market demand and innovative technology are the main drivers. In this article, we will introduce the current chicken feed market situation, and analyze how to develop a successful chicken feed production business plan and the key steps of the chicken feed production process. At the end of this article, I will present a practical example of a broiler chicken feed recipe. Through this article, I hope that you will be able to have a clearer understanding of the feed industry landscape and challenges, and provide useful references and insights for future business plans and production processes.

Chicken Feed Processing Business Plan

Profitability of Chicken Feed Production Businesses: Feed Market Analysis

To answer the question "Is chicken feed business profitable?", I will show you clearly the huge business potential of the chicken feed industry through some feed production statistics below.

Chicken Production Statistics and Forecasts

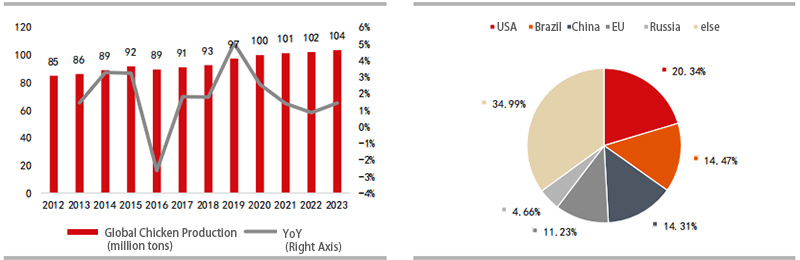

Global Poultry Production Increases at an Annual Compound Growth Rate of 1.66%

The global chicken production is generally showing a steady growth trend, except for 2016 which witnessed a slight decline in production. The total global chicken production was 84.91 million tons in 2012, and is expected to reach 103.52 million tons by 2023, with a compound annual growth rate of 1.66%. It is foreseeable that the global chicken farming scale will continue to increase and the chicken feed demand will continue to grow for a long time to come.

Global Chicken Consumption Rises at an Annual Compound Growth Rate of 1.65%

Since 2012, chicken meat consumption has been showing an upward trend, and the trend is the essentially same as chicken meat global production. In 2016, the global consumption of chicken meat amounted to 87.66 million tons, and by 2023, the consumption of chicken meat amounted to 100.89 million tons, with a compound annual growth rate of 1.65%.

Poultry Market Size Expected to Grow at an Annual Compound Rate of 4.2%

According to a report by the EU Ministry of Agriculture and Rural Development, the poultry feed market size is projected to grow from USD 205.33 Billion in 2023 to USD 252.22 Billion by 2028, at a CAGR of 4.20% during the forecast period (2023-2028). This is because poultry is considered by consumers as an inexpensive, healthy, and sustainable product option. Hence, increasing demand for the production of healthy and nutritious poultry meat is expected to drive market growth. The chicken feed market is expected to hold the majority share of the poultry feed market because chicken meat is the most dominant poultry meat.

Lucrative Chicken Feed Production Business Plan Comprehensive Guide

To successfully produce chicken feed, chicken feed manufacturers often have to go through some of the following key steps to ensure the viability and success of their chicken feed production business plan.

- Gather information on chicken feed prices, specifications, and types.

- Determine chicken feed production scale based on market demand and production capacity.

- Develop feed formulas according to the growth and development needs of chickens.

- Establish a raw material procurement supply chain to ensure quality and stable supply.

- Schedule production plans based on chicken feed market demand and raw material availability.

- Implement strict control measures across chicken feed production processes to ensure feed quality and safety.

- Conduct market promotion activities, including partnerships with farms, participation in chicken industry exhibitions, and promotional campaigns.

- Regularly adjust and optimize chicken feed production plans based on market feedback and production status.

Understanding the Chicken Feed Manufacturing Process Step-by-Step

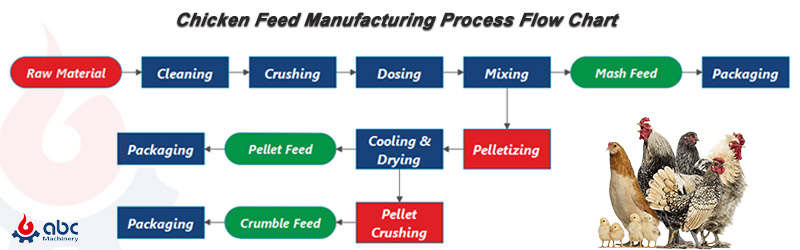

Depending on your business plan, whatever you want to make powdered, pelleted or crumbled chicken feed and whatever you want to make chicken feed for layers and broilers. I will provide a generic chicken feed processing flowchart. This chicken feed processing flowchart will give you a brief introduction to the chicken feed making process. I hope you will learn how to make chicken feed from it.

Chicken Feed Processing Design Flow Chart

- Cleaning: Poultry feed plants mainly clean grain feed and its by-products. The raw material cleaning process is not only to guarantee the final chicken feed product quality but also to reduce the wear and tear of the chicken feed making machines in the chicken feed plant and ensure the smooth operation of the chicken feed making line.

- Crushing: In the chicken feed production line, the purpose of the crushing process is to increase the surface area of feedstocks and improve the uniformity of mixing and the digestibility of chickens. The size of crushed feed ingredients varies according to the growth and development stage of the chicken.

| Different Growth Period | Chick | Medium Chicken | Adult Chicken |

|---|---|---|---|

| Suitable Particle Size / mm | ≤1.0 | ≤2.0 | 2.0~2.5 |

- Dosing: When dosing, the chicken feed formula should be strictly followed. The order of dosing is: first big material, then small material.

- Mixing: When producing chicken feed, it is important to grasp the mixing time. The mixing time is too short, so the material is not fully mixed, affecting the mixing quality. Too long a mixing time will make the material over-mixed to cause separation, which also affects the quality. Because the optimal mixing time of different chicken feed mixing machines is also different. Therefore, if you want to know the chicken feed mixer machine and its optimal mixing time, you can directly consult us.

Chicken feed making process to this step, powder chicken feed (chicken mash feed) production has been completed basically. However, it is important to note that usually powdered chicken feed is added with water to be used when feeding chickens.

- Pelletizing: In chicken feed processing plants, pelletizing processing is usually done by flat die chicken feed pellet machine and ring die chicken feed pellet making machine. The diameter of chicken feed pellets also varies depending on the growth period of the chickens. Adult chicken and chick feed pellets have a diameter of 3.0 ~ 4.0 mm, while adult broiler and breeder feed pellets have a diameter of 5 mm. The length of the feed pellet is 1.5 ~ 2 times the diameter of the pellet. Chick feed is usually processed into larger pellets before being crushed by a pellet crusher to make crumble feed.

In this step, the chicken feed pellet products produced by the chicken feed pellet mill have been basically completed.

- Cooling and Drying: The feed is cooled to room temperature through a cooling system, which helps to extend the shelf life and shape the pellets. The moisture content of the feed is usually kept below 13.5% to ensure that it can be stored safely.

- Pellet Crushing: Chicken feed crushed pellets (crumble feed) are commonly used for feeding chick. Besides, crushed chicken feed is also used to improve the palatability and digestibility of chicken feed. However, due to the dispersed texture of crumbled chicken feed, it also tends to cause picky eating and feed wastage.

At this step, the production of chicken crumble feed is basically completed.

- Packaging and Storage: The animal feed should be packaged in woven bags with a plastic liner. It is then placed on a wooden or wire frame some distance off the ground in a cool, ventilated dry place.

Chicken Mash Feed & Chicken Crumble Feed & Chicken Pellet Feed

An Example of High-Quality Formula for Making Chicken Feeds

Both commercial chicken feed factories and farmers need to consider the actual situation and be flexible in adjusting their chicken feed formulations when producing chicken feed. This is because various factors such as growth stage, health status and feeding environment affect the effectiveness of chicken feed. Therefore, chicken feed producers need to adjust their chicken food formulations according to the state of chickens in time to ensure their health and nutritional needs.

Different types of chickens such as laying hens, broilers and breeders have different nutritional requirements at different periods such as growing, laying and finishing periods. Therefore, individualized chicken feed formulation is important to ensure the overall healthy development of chickens.

Contact us directly for more information about processing chicken feed.

Here is a chicken feed recipe for your reference:

| Raw Material Name(%) | 1~2 Week | 3~4 Week | 5~6 Week |

|---|---|---|---|

| Corn | 59.90 | 66.78 | 73.27 |

| Soybean Meal | 27.40 | 22.20 | 16.90 |

| Poultry Meat Meal | 5.00 | 5.00 | 5.00 |

| Poultry Oil | 3.90 | 2.86 | 2.00 |

| Stone Meal | 1.20 | 1.23 | 1.13 |

| Calcium Phosphate | 1.43 | 0.90 | 0.65 |

| Salt | 0.40 | 0.36 | 0.37 |

| DL-Methionine | 0.18 | 0.08 | 0.09 |

| Choline Chloride(60%) | 0.20 | 0.20 | 0.20 |

| Lysine Hydrochloride | 0.04 | 0.04 | 0.04 |

| Premix | 0.35 | 0.35 | 0.35 |

Through the analysis in this post, we can understand that chicken feed mill is still a profitable investment option now and in the future. If you are debating the choice of a chicken feed production machine manufacturer and complete chicken feed production line supplier, give us a thought. ABC Machinery has more than 20 years of experience in animal feed processing equipment. We have successful animal feed projects in many countries around the world, such as Australia, New Zealand, Chile, Indonesia, Nigeria, South Africa, Kenya, and Zambia. If you need anything, don't hesitate to contact us directly for free answers!