Making High Quality Pourlty and Livestock Feed Pellets

More and more farmers tend to make feed pellets for their own chicken, goose, cows, goats, and more to reduce the feeding cost, which is definitely a great idea. In order to meet more customer’s demands, ABC Machinery not only offer large scale feed pellet plant, but also provides the small scale animal feed production line that is in compact size and is very much suitable for home use or farm use. In addition, we also offer customized animal feed production business plan to help our customer know the feed pelletizing industry quickly.

600~1000kg/h Small Animal Feed Pellet Production Line

Small Complete Set of Feed Processing Machine for Making Pelleted Feed

- Production Output: 600~1000kg per hour

- Diameter of Feed Pellets: φ1.5~φ8mm

- Diameter of Pellet Die: φ250mm

- Main Equipment: Ring Die Feed Pellet Mill, Mixer and Conveyors

- Application: Make feed pellets for chicken, cattle (cow), sheep (goat), horse, pig, geese, pigeon, ostrich, camel, and so on.

- Raw Materials Can Process: Corn, wheat bran, alfalfa, oilseed meal (soybean oil meal, sunflower seed oil meal, cotton seed oil meal, etc.), wheat straw, fish meal, corn meal and rice husk, etc.

This complete animal feed pellet production unit is BEST choice for home or farm use. Its small size takes up small scale space and the ring die pellet mill promise relatively high production output. Most importantly, the cost is relatively low compared to the same capacity animal feed pellet machine. For detailed price, please inform us your raw materials, animal and purpose and more. Then, we will offer you the customized equipment and the most favorable price!

Small Animal Feed Pellet Mill Production Video

Why Choose Our Small Animal Feed Pellet Production Set

- The complete set of animal feed pellet production line is designed with transmission, mixing and pelletizing, so it is easy to operate it due to its simple and complete structure.

- The pellet machine adopts SPB powerful and narrow belt transmission system, which has ideal transmission efficiency, stable rotation, high output, low noise, no oil leakage and pollution, and lower maintenance cost of components.

- This model has 1.5-12mm between a variety of aperture and thickness of the ring touch, users can choose according to different needs, in oder to obtain the best technical and economic benefits.

- The unit is suitable for use in small and medium-sized breading plants, poultry raising plants, individual professionals and contractors.

How to Reduce Animal Feed Pellet Production Cost?

1-2ton/h Pelleted Feed Production Factory Layout

2-5ton Pelleted Feed Processing Plant Setup

Generally, there are several factors that decides the cost of animal feed pellet production, including raw materials cost, equipmen price or equipment modernization and reinvestment, depreciation and energy consumption. For most of animal feed pellet mill company, the top priority is to improve the equipment performance and lower energy consumption to reduce the cost. That’s why itis very important to choose an reliable and powerful supplier and manufacturer. (Related Post: Setting up an Animal Feed Manufacturing Company >>)

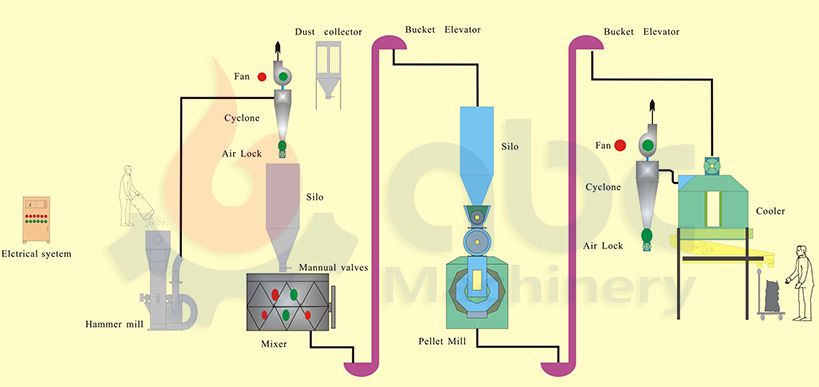

Poultry & Livestock Feed Production Process Design

The advanced animal feed pellet mill plant not only can improve the production capacity, but also can help to lower the maintenance and energy cost. ABC Machinery provides various models of feed mill equipment to meet customers’ different demands for efficient animal feed pellet plant, including cattle feed plant, poultry feed plant, fish feed pellet mill, etc. Our feed pellet mill is designed with efficient transmission and pelletizing system and updated technology. All of our equipment can achieve automatic production and can ensure the flexibility and quality of final pellets. In addition, it can also save the maintenance cost on the equipment and reduce the downtime.

| Feed | Pig feed | Egg poultry feed | Meat poultry feed | Aquatic feed | Ruminant feed | Other feeds |

|---|---|---|---|---|---|---|

| Ten thousand tons | 9720 | 2984 | 6509 | 2211 | 1004 | 360 |

Importance of Pelletizing for Animal Raisers and Farmers

Pelleting is an everyday process in compound animal feed production. The changing of animal feeds into pellets has its advantages about the nutritional value and the final product handling. Every single pellet contains specified nutrients by the nutritionist as it is made by combining the ingredients. In this way, every animal will eat a balanced diet and selective eating behavior will be avoided.

Start Your Own Poultry / Cattle Feed Processing Business

A lot of time is wasted in the production of feed mash due to mill blockage. These problems are significantly reduced due to advanced machinery in pellet production. Transportation of the compounded feed is also improved through pelleting. The pellets are denser hence less in size compared to the feed mash. Therefore more pellets can be transported per unit transit. Another advantage is that pellets have less dust after packaging and therefore cross-contamination is highly reduced during transportation.

There are several factors to consider in the pelleting process from the formula to the controlling limits, rolling gap, and the pellet mill die provisions. The main factor is to govern the best accommodation between the quality of pellets and energy utilization, while producing the intended amount.

Condensation is improved by the addition of steam hence making better the pelleting process. This yields in producing more quality pellets per unit time and use of less energy. More pressure are added to the die by adjusting the roller gap giving a higher quality of the pellets. This will impact negatively on energy utilization because more energy will be used to push the feed via the die. This may be fixed by replacing the present die with a thicker one. The addition of steam has its limitations. Adding excess steam might cause the roller to slide and the results of the roller slide are dire. The workers are always careful because replacing the die is time-consuming and the damaged die cannot function again.

In conclusion, making pellets to feed animal is absolutely helpful both from cost and animal growth. Now, more and more small scale farmer owners have realized this problem, they are trying to seek more suitable animal feed making machine for their own use. If you are also the same, please contact us. We can help you solve all the questions and problems about the animal feed production.