Various equipment required for the piloting of biomass briquetting in Somalia

Biomass Briquetting & Pelleting Machine for Sale >>

(This is an inquiry from our customer who are very interested in building a biomass pelleting/briquetting line)We need a price idea, the technical data sheet (including pictures, demonstration video or similar), and local availability Nairobi/delivery periods for the various below equipment.

All price estimates should be on basis of CIF Mombasa/Nairobi and include the equipment plus replacement parts for 2 years of operation. A minimum warranty of 1 year is required.

Raw materials to be used are: biomass and agricultural waste like straw, stalk, wood chip, tree branch, forest waste, yam, peanut, husks, maize, wheat, beans of all grain

Smaller equipment:

All the below mills/threshers should fulfil the following:

· Large feeding port, simple construction, convenient operation, high efficiency, low power consumption;

· Output size: 2-6mm with different size of sieves/filters;

· Output quantity: 150-600 kgs/hour.

I found the following descriptions for the type of machines we want to consider:

1. Hammer mill with 15 hp diesel engine;

2. Electric motor hammer mill with 7.5kw/380V electric motor;

3. Small hammer mill for wood pellets with 5.5kw power motor;

4. Shredder (universal masher) steel with diesel engine;

5. Professional composter for shredding hedge trimmings, tree off-cuts and branches up to 50mm with diesel engine.

Larger equipment:

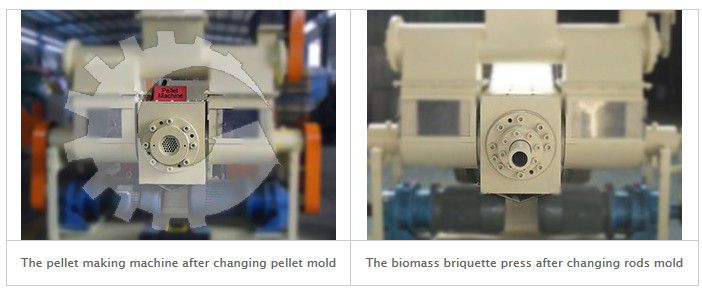

6. Biomass briquetting/pelleting machine with direct feeding system – diesel operated

General: Heavy structure with standard design, low energy consumption, low maintenance requirements. Production capacity: 700-1500 kgs/hour. Finished product size: high density with 45-90mm diameter. Input size: up to 20mm size; Moisture content: 9-12%.

7. Posho mill – diesel operated