Do you know that rice husk pellets can be used as fuel? Lately a small set of biomass pelletizer for rice husks / hulls are fished manufacturing and ready to be delivered to one our our client in France. The main eqipments of this small pelletizing unit are small pellet mill (ZLSP-R 250B), rice husk crushing machine (11kW) and converyor (4.5m).

Rice Husk Pelletizer and Crusher

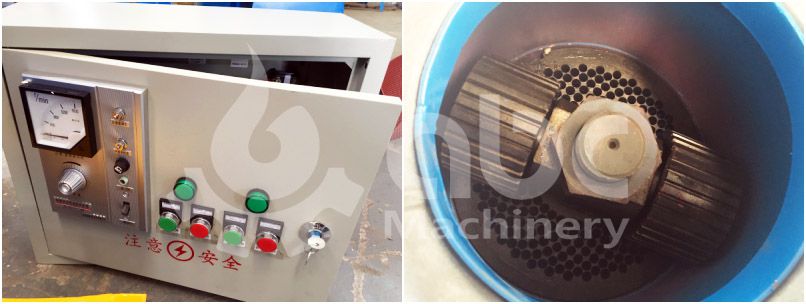

Electric Cabinet and Flat Die & Roller Assembly Set

Conveying Machine

Test-running Small Biomass Pelletizer Unit for Rice Husk

Paddy rice constitutes of approximately 72% rice, 22 % husk, and 6% bran. Figures indicate that up to 70% of the husks are left idle and will remain in the environment for a long time due to their low biodegradability. And to take advantage of the ready availability, large volumes and need for better fuel, people are now turning to rice husks. This product is turned into pellets which burn better and more-efficiently than charcoal, firewood, and other products. The husks are rich in lingnocellos, fiber content, cellulose and hemicellulose (carbon sugar fibers). They have a caloric value is approximately 14 MJ/kg while that of bunker oil or diesel is 40.5 MJ/kg.

Rice Husks for Test Running

According to statistics, paddy rice is the staple food for more than half the people in the world. This essential commodity is cultivated by over 20% of the people and covers about 1% of the earth’s surface. The report goes further to show that annual production is steadily increasing at about 16.48 million tons and the total production in 2011 was 718.3 million tons. It is estimated that as of 2020, the annual demand will be about 780 million tons. This is without-a-doubt a lot of paddy.

Rice Husk Pellets Made by the Small Plant

Turning Husks into Pellets

With more than 100 million tons of rice husks produced annually, people are turning to paddy rice pellets as an alternative fuel. The pellets are processed using specialized machines or plants that range from 50 kg/h up to 20 ton/h. The following are the main stages:

- Screeners: Also known as Sievers, this unit removes dirt, dust, leaves, debris and other impurities.

- Grinder: This part is also referred to as the hammer and pounds the husks into a fine powder.

- Pelletizer (pellet mill): It compresses the powdered husks into fuel pellets.

- Packing machine: The pellets are packaged in the chosen sizes ready for shipping and use.

Why Rice Husk Pellets?

- Efficient: The heat produced by the pellets is better with a combustion rating of 95% plus and lasts much longer.

- Environmentally-Friendly: The biomass fuel eases pressure on non-renewable fuels, burns better and pollutes less. The husk pellets also produce lesser ash.

- Versatile: the pellets can be used with pellet stoves, traditional stoves, boilers, heating furnaces, fireplaces and many other heating appliances.

- Convenient: Due to their compacted nature and high density, the pellets are smaller, lighter and easy to store and carry. Its low moisture content of 7-8% means they burn quicker and produce less soot or smoke.

Rice husk pellets seem to be the way to go when it comes to reliable biomass fuel. The commodity is easily accessible and readily available, the volumes are ever increasing, and it is both user and environmentally-friendly. You can be part of the change by investing in a quality rice husk pellet making machine or plant.