What is Hops Pellet?

Do you like beer? Do you know how to make beer? Maybe, you know that the beer is brewed with the grains and water. Apart from water, grain and yeast, there is one important ingredient used in beer brewing and that is hops.

Making Hops Into Pellets

Hops are one of the essential if not basic ingredients in brewing beer. Before using them for brewing, the hops flowers are always compressed into pellets to make the basic ingredient through the hops pellet production plant through a series of processes. In addition to hops used to make pellets, beer waste can also be produced into pellets for feeding animals.

The hops used in preparing beer belong to the hemp family, although only the flower of the hop plant is used in brewing. The hops are rich in essential oil which bears a very bitter taste. The bitterness is very important because it acts as a preservative and also reduces the sweetness in the malt so as to create a more balanced beer. Brewers can balance the ratio of bitterness to sweet maltiness in the end product, which is the final beer by regulating the type of hops used in the brewing process when they are introduced into the wort and the time it takes to be completely boiled. Generally, the hoppiness in a beer is the bitter taste of a particular ingredient used in brewing and how it affects other tastes or flavors in the beer.

Main Process of Hops Pellet Production Plant

Generally speaking, the hops pellets are made from leaf hops that have been crushed into a powder or small size less than 5mm with a crushing machine. The powder is then pelletized by passing it through a natural pelletizing mill. The whole process is as followed:

Step 1 – Harvesting the Hops

The first step is harvesting the hops when they are ready before you go into the hops pellet production. For small scale hops farmers, the hops can easily be hand picked straight from their bines in the farm by using a lift and then they are sorted out using a mesh screen. However, for large scale hops farmers (mini pellet mill), they can use advanced equipment such as sorter machines and hop pickers to harvest them with ease.

Hops harvesting and Drying

Step 2 – Drying the Hops

After harvesting the hops, the next major step is drying them. This is done to get rid of the moisture from the leaves and also conserve the unstable lupulin. This process enables you to store the hops for an extended period of time without spoilage. The amount of crop you have harvested will determine the method you use for drying them. If you have many crops you will be required to make an oast to handle the large amount of crops.

Step 3 - Crushing the Hops

This process involves using a hammer mill to crush the dried hops into smaller sizes. Ensure that the pieces are as tiny as possible but do not turn them into dust. Rotate the hammer at a very high speed so as to crush and swallow the hops and repeat this process if you notice large particles. Crushing helps the hops attain a consistent form and proper moisture content that is required for further processing.

Step 4 – Pelletizing the Hops

Use a hops pellet mill to make hops pellets. Desiccated hops go through the pellet mill and are compressed by the roller and die. The effect of the pressure makes the material condensed and then removes it through the perforations in the die. It should be noted that during the process of pelletizing hops for brewers, the heat generated may cause damages on the hops if the process is rushed and the machines are not allowed to cool down more often. (More about small pellet mill>>)

Industrial Hops Flower Pellet Production Plant / Line (Click here if you are intereted in small pelletizing unit)

You can choose the most suitable one type based on your requirement and conditions, we are usually offering the following two types of hops pellet machines:

| Type | Output |

|---|---|

| Small flat die pellet mill | 500~1000KG/H |

| Large ring die pellet making machine | 0.5~10Ton/H |

Feel free to send us an email if you are planning for starting a hops pelletizing business or interested in our pellet production plant. Tell us your needs and situation such as planned cost, capacity requirement, factory location and so on. Then we will supply the most suitable plan and machinery for you!

Step 5 – Cooling the Hops Pellets

Ensure that the hops pellets have cooled completely. To do this, spread the pellets out and give them time to cool off and dry naturally. For large scale hops pellets production, you may consider a pellet cooler.

NOTE:

-

The hops powder contains all the lupulin material of unprocessed leaf hops and vegetative materials which can be used in place of leaf hops in the brewing process. Normally, the equal amount of hops pellets can take up about 10-15 % of additional bitterness as compared to the whole leaf.

-

During the hops pellets production, the hops pellets are usually put together in an inert gas like nitrogen or under vacuum so as to decrease the speed at which they deteriorate. Pelletizing hops for brewers involves compressing the hops to ensure that they have a light weight so that they are less vulnerable to destruction and also easy to store.

Global Market Demand for Hops Pellets Production Plant

Wide Raw Material Distribution

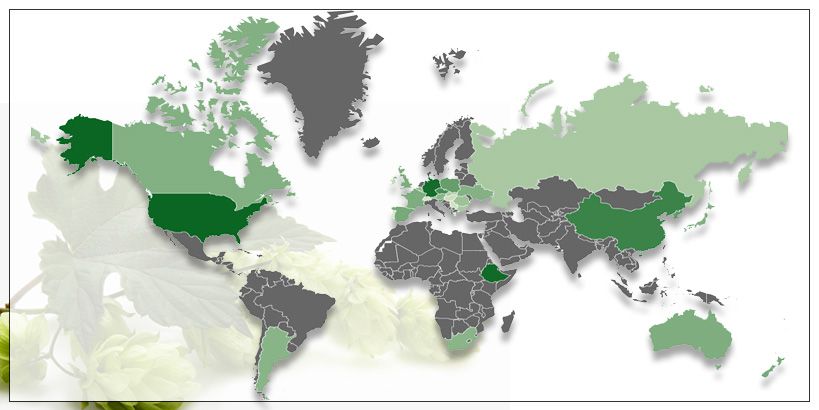

Global Hops Distribution

The international market for hops pellets supplies hops grown in relatively few countries/regions of the world. Due to the sensitivity of snakeweed, hops are mainly distributed in the northern hemisphere, between 30°-60°N, mainly plants in Western Europe, Northwest USA and China. Therefore, it has a large market share for people who would like to start a hops pellet business plan.

Large Demand for Hops Pellets

Global Hops Market 2020-2024

Due to the explosion in the number of craft breweries today, and the increasing variety and volume of craft beers, especially in the United States, where there are now nearly three thousand craft breweries (other countries/regions include Japan, the United Kingdom, Germany and China), the demand for hops pellet is strong and growing.

Advabtages of Hops Pellet for Brewer

Hops pellets are the preferred choice for most craft brewing operations for its unique advantages:

- When the hops are crushed by the hops pellet pelletizer machine, they assume more surface area contact thus increasing utilization.

- The condensed state and light weight of hops pellets makes them easy for storage and less vulnerable to destruction as opposed to other forms.

- Since they have been compressed into smaller forms by the hops pellet mill, their shelf life is elongated because they are not out in the open for heat and oxygen to get in.

- The produced hops need less packaging and storing space since they are in pellet form through the pelletizing process. This also makes it for measuring quantities, disposing the used hop debris and also easy for shipping.

Hops VS Hops Pellets

In short, hop pellets offer unique advantages over other forms of hops in brewing, while strong market demand and insufficient supply make hop pellets a huge market potential worldwide. On the other hand, with the development of pelletizing technology and improvements in pelletizing machines, there are a large number of hop pelletizing machines available for people who want to start a hop pelletizing business.

When you plan to start the hops pellet production plant as a business or if you have interest in making beer waste/residues into pellets for feeding animals, please feel free to contact us, we will offer you the high quality equipemnt and best service!